A semi truck clutch works by engaging and disengaging the engine from the transmission to change gears. When the driver presses the clutch pedal, the pressure plate disengages the clutch disc from the flywheel, allowing the driver to shift gears.

Semi truck clutches are essential components that allow the driver to change gears smoothly, transferring power from the engine to the wheels. The clutch system consists of the clutch pedal, linkage, pressure plate, clutch disc, and flywheel. Understanding how the clutch works is crucial for truck drivers and maintenance professionals to ensure optimal performance and longevity of the truck.

We’ll delve into the detailed functionality of a semi truck clutch, explaining its role in the overall operation of the vehicle. Additionally, we’ll explore the key components and the process of engaging and disengaging the clutch to change gears effectively.

Credit: m.youtube.com

Navigate As You Want:

Components Of A Semi Truck Clutch

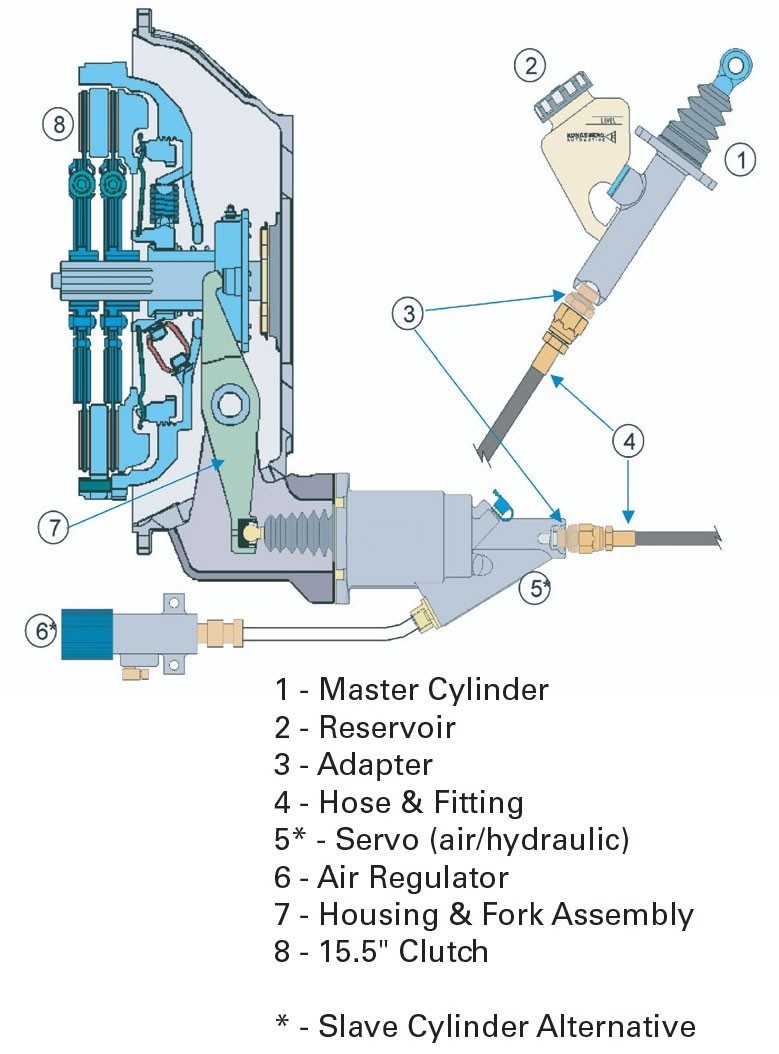

A semi truck clutch is composed of three main components: the flywheel, pressure plate, and clutch disc. The flywheel is a heavy circular metal disk attached to the engine’s crankshaft. It stores rotational energy and smooths out engine vibrations. The pressure plate is bolted to the flywheel and exerts pressure on the clutch disc. It is responsible for transmitting engine power to the transmission. The clutch disc is sandwiched between the flywheel and the pressure plate. It consists of a friction material that allows it to grip the flywheel and pressure plate, enabling power transfer to the transmission. When the clutch pedal is depressed, the pressure plate releases the clutch disc, disengaging the engine from the transmission. In turn, shifting gears becomes possible. When the clutch pedal is released, the pressure plate applies pressure to the clutch disc, engaging the engine with the transmission once again.

Functioning Of A Semi Truck Clutch

Engaging the Clutch When a semi-truck clutch is engaged, the pressure plate pushes the friction disc against the flywheel. This action causes the transmission input shaft to turn and synchronizes with the engine’s speed. The synchronized speed of the transmission input shaft allows the driver to shift between gears smoothly and efficiently.

Disengaging the Clutch When the semi-truck clutch is disengaged, the pressure plate releases the friction disc from the flywheel. As a result, the transmission input shaft is no longer turning and disconnects from the engine’s speed. This disconnection enables the driver to change gears or come to a complete stop without stalling the engine.

Common Issues And Maintenance

The semi truck clutch works by transferring power from the engine to the transmission. One common issue is the worn clutch disc, which can cause a jerking motion during gear shifting. This problem is often due to regular wear and tear and requires replacement. Another issue is a slipping clutch, which can be caused by oil contamination or a worn pressure plate. This may lead to difficulty shifting gears and should be addressed promptly. Periodic clutch adjustment is essential for maintaining optimal performance and should be performed according to the manufacturer’s specifications to ensure smooth operation.

Credit: timstruckcapital.com

Upgrading A Semi Truck Clutch

When it comes to upgrading a semi truck clutch, there are heavy duty clutch options and performance clutch options available. These upgraded clutches offer improved durability, performance, and reliability for heavy-duty applications.

Heavy duty clutch options are designed specifically for hauling heavy loads and offering better torque transfer, allowing the vehicle to handle increased power without sacrificing clutch life. These clutches are built with high-quality materials and advanced technology to withstand the demands of long-hauling and off-road driving.

On the other hand, performance clutch options are aimed at drivers looking to enhance their vehicle’s performance and responsiveness. These clutches offer smoother engagement, quicker shifts, and improved power transfer. They are engineered for high-performance applications and can handle increased torque and horsepower.

Whether you need a heavy duty clutch or a performance clutch, upgrading your semi truck clutch can significantly improve your driving experience and extend the life of your transmission. Consult with a reputable supplier to find the best clutch option for your specific needs.

Credit: www.eaton.com

Frequently Asked Questions Of How A Semi Truck Clutch Works

How Does A Semi Truck Clutch Work?

A semi truck clutch is a mechanism that engages and disengages the power transmission between the engine and the transmission. When the clutch pedal is pressed, it disengages the clutch, allowing the driver to shift gears. Releasing the pedal engages the clutch, transferring power from the engine to the transmission.

What Are The Components Of A Semi Truck Clutch?

A semi truck clutch consists of three main components: the clutch disc, pressure plate, and flywheel. The clutch disc is sandwiched between the flywheel and the pressure plate. When the clutch pedal is pressed, the pressure plate releases pressure on the clutch disc, allowing for gear changes.

How Often Should A Semi Truck Clutch Be Replaced?

The lifespan of a semi truck clutch varies depending on several factors, such as driving conditions and maintenance. On average, a clutch can last anywhere from 50,000 to 150,000 miles or more. It is important to inspect the clutch regularly and replace it if signs of wear, such as slipping or difficulty shifting gears, are observed.

What Are The Signs Of A Failing Semi Truck Clutch?

Some signs of a failing semi truck clutch include slipping or difficulty shifting gears, a burning smell, a vibrating clutch pedal, or unusual noises when engaging or disengaging the clutch. If any of these symptoms are experienced, it is best to have the clutch inspected by a professional to determine if replacement is necessary.

Conclusion

To conclude, understanding how a semi truck clutch works is crucial for truck drivers and enthusiasts alike. With its complex yet efficient design, the clutch plays a crucial role in the smooth operation of the vehicle, allowing for seamless gear shifting and increased performance.

By grasping its inner workings, drivers can enhance their driving experience and maintain their truck’s longevity. Familiarizing oneself with the intricate details of a semi truck clutch is a key step towards becoming a knowledgeable and skilled driver in the world of heavy-duty transportation.