Semi truck engine brakes work by reducing engine power to slow down the vehicle and increase braking efficiency. By restricting airflow into the engine cylinders, the engine brake creates resistance that helps in slowing down the vehicle.

Semi trucks rely on engine brakes, also known as Jake brakes, to provide additional braking power when descending steep inclines or when traditional brakes may overheat. By manipulating the engine’s compression and decompression cycles, engine brakes effectively assist in slowing down the truck, allowing for safer and more controlled driving.

Understanding how semi truck engine brakes work is crucial for truck drivers and fleet managers to ensure optimal vehicle performance and safety on the road. We will dive deeper into the functionality and benefits of semi truck engine brakes.

Credit: www.jacobsvehiclesystems.com

Navigate As You Want:

Types Of Semi Truck Engine Brakes

Semi truck engine brakes are designed to help slow down the vehicle and reduce wear on the service brakes. There are two main types: compression brakes and exhaust brakes. These brakes work by manipulating the engine’s internal components to create braking power, providing greater control and safety on the road.

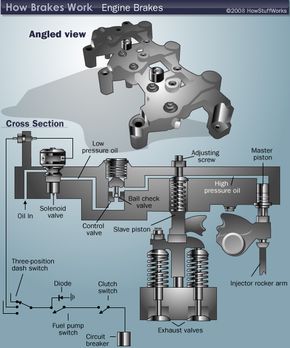

Semi truck engine brakes are crucial for maintaining control and ensuring safety while driving these heavy vehicles. There are two main types of engine brakes commonly used in semi trucks: Jake brakes and compression brakes. Jake Brakes: Also known as “Jacobs Engine Brake,” Jake brakes work by opening the exhaust valves at the top of the compression stroke, releasing compressed air and reducing the engine’s power. This converts the engine into an air compressor, creating resistance that helps slow down the truck. The energy generated during this process is dissipated through the exhaust system. Compression Brakes: Compression brakes, also called “exhaust brakes,” work by restricting the exhaust flow, causing backpressure on the engine. This backpressure helps slow down the vehicle by allowing the engine to work against itself, using the compression strokes to slow the truck down gradually. Both Jake and compression brakes provide additional stopping power, reducing wear on traditional braking systems and enhancing the overall safety of semi trucks.

Credit: m.youtube.com

How Jake Brakes Work

Jake Brakes, also known as engine brakes, are a mechanism that helps slow down a semi-truck without using the conventional brakes. The mechanism of Jake Brakes involves manipulating the exhaust valves to create back pressure in the engine, which slows down the truck by reducing the engine’s power output. One of the key benefits of using Jake Brakes is enhanced control and reduced wear on the vehicle’s standard friction brakes.

How Compression Brakes Work

Compression brakes work by reducing the engine’s power output, creating resistance in the cylinders. This restriction slows down the vehicle without relying solely on traditional braking methods. The system works by closing off the intake valve, so the engine’s power compresses the air, turning it into an air spring. This energy is released, generating braking power. The advantages of compression brakes include reduced wear on traditional brake systems and improved overall braking efficiency. However, there are limitations such as decreased effectiveness at lower speeds and potential maintenance costs. Despite these limitations, compression brakes provide an essential safety feature for semi-trucks, improving overall braking capabilities.

Comparison Of Jake Brakes And Compression Brakes

Engine brakes are essential safety features for semi trucks, helping drivers to slow down and control their speed on steep slopes. Two common types of engine brakes are Jake Brakes and Compression Brakes, each operating differently.

Jake Brakes work by opening the exhaust valves as the engine approaches the compression stroke. This releases compressed air and creates backpressure, effectively slowing the truck down. On the other hand, Compression Brakes work by interrupting the intake stroke, preventing fresh air from entering the engine cylinder and reducing its power.

These two engine brakes have different application scenarios. Jake Brakes are commonly used in heavy-duty applications, ideal for long downhill grades and steep slopes. Compression Brakes, also known as “jakeless” engine brakes, are more suitable for light-duty applications or areas with noise restrictions, as they are quieter compared to Jake Brakes.

| Features | Jake Brakes | Compression Brakes |

|---|---|---|

| Operation | Uses exhaust valves and creates backpressure | Interrupts intake stroke to reduce engine power |

| Application | Heavy-duty applications, long downhill grades | Light-duty applications, noise-restricted areas |

Credit: auto.howstuffworks.com

Frequently Asked Questions For How Do Semi Truck Engine Brakes Work

How Do Semi Truck Engine Brakes Work?

Semi truck engine brakes, also known as Jake brakes, use the engine’s compression to slow down the vehicle. When the driver releases the accelerator pedal, the system opens the exhaust valves, creating resistance that helps slow down the truck. This reduces wear on the truck’s regular braking systems and can improve overall safety on steep grades.

Conclusion

Semi truck engine brakes play a crucial role in ensuring the safety and longevity of the vehicle. By effectively reducing speed and relieving pressure on the regular braking system, engine brakes help prevent wear and tear, reduce maintenance costs, and provide better control while descending steep slopes.

Understanding how these advanced braking systems work is essential for every truck driver and can contribute to overall road safety. So, the next time you encounter a large truck on the highway, you’ll have a better understanding of the impressive technology behind their stopping power.

Stay safe on the road!