To determine the torque for truck lug nuts, generally, it is recommended to tighten them to about 90-120 ft-lbs. Proper torque ensures safe wheel installation and prevents damage or accidents.

When tightening lug nuts on a truck, it is crucial to use a torque wrench and follow the manufacturer’s specifications to ensure proper tightness and safety standards. Over-tightening or under-tightening can lead to wheel issues such as loosening, vibrations, or even accidents.

By following the appropriate torque levels, you can maintain the integrity of your truck’s wheels and ensure safe driving conditions. Remember, safety always comes first when it comes to vehicle maintenance.

Navigate As You Want:

- Why Torque Matters For Truck Lug Nuts

- Recommended Torque Specifications For Truck Lug Nuts

- Tools And Techniques For Torquing Truck Lug Nuts

- Common Questions About Torquing Truck Lug Nuts

- Best Practices And Tips For Torquing Truck Lug Nuts

- Frequently Asked Questions Of How Much Torque For Truck Lug Nuts

- Conclusion

Why Torque Matters For Truck Lug Nuts

|

The importance of proper torque for truck lug nuts cannot be overstated. The correct torque ensures that the lug nuts are secured to the wheel hub properly, preventing them from coming loose during operation. The impact of insufficient torque on lug nuts can lead to loosening of the nuts over time, posing a safety risk. On the other hand, the impact of excessive torque can cause the studs to stretch, affecting the integrity of the wheel assembly. |

Recommended Torque Specifications For Truck Lug Nuts

When it comes to truck lug nuts, it’s important to follow the recommended torque specifications to avoid any damage or danger. Knowing how much torque to use ensures proper tightness and safety for your truck’s wheels.

| Manufacturer Recommendations | Always follow the manufacturer’s guidelines for proper torque specifications. |

| Wheel Lug Nut Size Guide | Refer to a lug nut size guide to match the correct torque spec for your specific wheel. |

| Finding the Right Torque Specification | Ensure you use the appropriate torque wrench and technique to achieve the recommended torque. |

Tools And Techniques For Torquing Truck Lug Nuts

When torquing truck lug nuts, it’s essential to use the right tools and techniques. To determine how much torque is needed, refer to the vehicle’s manual or the manufacturer’s specifications. Over-torquing or under-torquing can cause damage or accidents, so always use a torque wrench for accuracy and safety.

| Properly torquing truck lug nuts |

| Use a torque wrench when tightening lug nuts for precise measurement. |

| Consider using a torque multiplier for heavy-duty trucks that require higher torque settings. |

| Tighten lug nuts by hand in a star pattern to ensure even distribution of force. |

| Refer to lug nut size guide and torque spec chart for appropriate settings. |

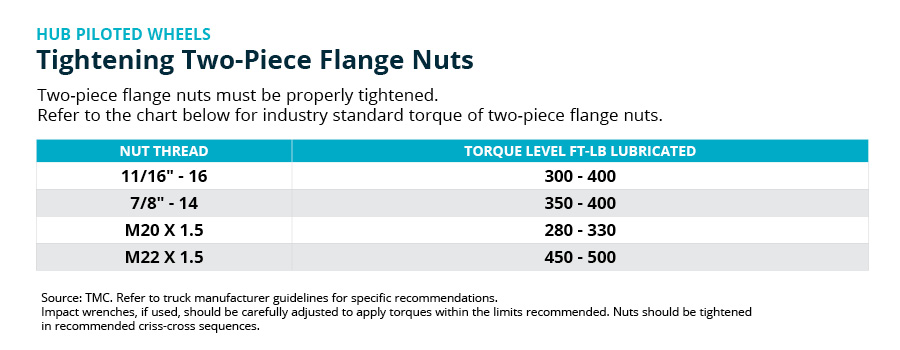

Credit: www.alcoawheels.com

Common Questions About Torquing Truck Lug Nuts

How Many Pounds of Torque Do You Need? The recommended torque for truck lug nuts typically ranges from 90 to 120 ft-lbs. Always refer to the manufacturer’s specifications for the exact torque required for your specific truck.

How Tight Should Lug Nuts Be? Lug nuts should be tightened using a torque wrench to the manufacturer’s recommended torque specifications. Over-tightening or under-tightening can lead to wheel damage and safety hazards.

What Size Impact Wrench is Needed for Lug Nuts? For lug nuts, you’ll need an impact wrench with enough torque to meet the manufacturer’s specifications. Generally, a heavy-duty impact wrench with at least 250-300 ft-lbs of torque should suffice for most truck lug nuts.

Best Practices And Tips For Torquing Truck Lug Nuts

Properly torquing truck lug nuts is crucial to prevent damage and ensure safety. Always refer to the manufacturer’s specifications for the correct torque setting. Over-tightening or under-tightening can lead to dangerous situations, so using a torque wrench is essential. Remember to follow the recommended torque range for each specific wheel lug nut size.

Inspecting Lug Nuts and Wheel Studs: Regularly inspecting the condition of your truck’s lug nuts and wheel studs is crucial for ensuring safe and secure wheel attachment. Look for any signs of wear, damage, or corrosion on the lug nuts and wheel studs. Check for any loose or missing lug nuts and ensure that they are tightened properly. When and How Often to Re-Torque Lug Nuts: It is recommended to re-torque the lug nuts on your truck’s wheels after the first 100 miles of driving, and then periodically thereafter. Re-torquing is necessary because the fasteners can settle and lose tension over time. Follow the manufacturer’s recommended torque values for your specific truck model, as this can vary depending on the type of wheels and lug nuts used. Avoiding Common Mistakes: One common mistake to avoid is over-tightening the lug nuts, as this can lead to damage to the wheel studs or even the wheels themselves. Use a torque wrench to ensure that the lug nuts are tightened to the correct specifications. Another mistake to avoid is under-tightening the lug nuts, as this can result in loose or detached wheels while driving. Always double-check that all lug nuts are properly tightened using a cross-pattern tightening sequence. By following these best practices and tips, you can maintain the proper torque for your truck’s lug nuts, ensuring safety and preventing any potential issues on the road.

Credit: m.youtube.com

Credit: www.pinterest.com

Frequently Asked Questions Of How Much Torque For Truck Lug Nuts

How Much Torque Do You Need For Truck Lug Nuts?

For truck lug nuts, you need 100-140 ft-lbs of torque to tighten them properly. Over-tightening or under-tightening can be damaging.

How Tight Should Truck Lug Nuts Be?

Truck lug nuts should be tightened to the recommended torque specified by the vehicle manufacturer. It’s essential to ensure proper tightness to avoid damage and ensure safety. Always refer to the vehicle’s specific torque specifications for the correct tightness of lug nuts.

What Torque Should Lug Nuts Be Set At?

Lug nuts should be set at a specific torque to prevent damage and ensure safety. The typical torque range for wheel lug nuts is 70 to 90 ft-lbs, depending on the size of the nut. It’s important to follow these specifications to avoid under or over-tightening.

Is 250 Ft Lbs Of Torque Enough For Lug Nuts?

Yes, 250 ft lbs of torque is enough for lug nuts.

Conclusion

Properly torquing your truck’s lug nuts ensures safety and prevents damages. Following the manufacturer’s recommended torque specifications is crucial to maintain the integrity of your vehicle’s wheel and its components. Over-tightening or under-tightening can lead to hazardous situations, so always use a torque wrench to accurately apply the right amount of force.