Semi truck brakes work through air pressure and hydraulic systems to stop the vehicle safely. These systems use brake drums, shoes, and friction materials to slow down and stop the truck when the brakes are applied.

Semi truck brakes are crucial for the safety of the vehicle and others on the road. Understanding how these brakes work is important for truck drivers and anyone sharing the road with them. We will delve into the workings of semi truck brakes, including the air brake system, hydraulic brake system, and the components that make them function efficiently.

We will also explore the importance of regular maintenance and inspection to ensure the brakes are in optimal condition. By the end of this article, you will have a comprehensive understanding of how semi truck brakes work and why they are vital for safe road transportation.

Credit: auto.howstuffworks.com

Navigate As You Want:

Air Brakes

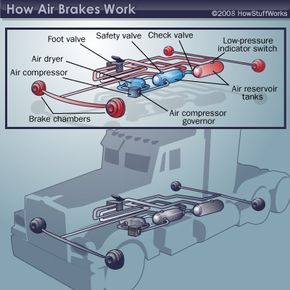

Air brakes are a crucial component of semi trucks’ braking systems that ensure safe and effective stopping. These brakes utilize compressed air to activate the braking mechanisms, offering excellent stopping power for heavy vehicles.

Working Principle Of Air Brakes:

The principle behind air brakes involves using air pressure to engage the brakes and release them when necessary. When the brake pedal is pressed, it initiates a process that compresses air within the brake system. This compressed air is then released into the brake chamber, which applies pressure to the brake pads or shoes, ultimately creating friction and stopping the vehicle.

Components of an air brake system include:

| Air compressor | Generates compressed air for the system |

| Brake pedal | Controls the application of brakes |

| Brake chambers | Convert air pressure into mechanical force |

| Brake pads or shoes | Create friction against the wheels to stop the vehicle |

| Brake drums or rotors | Provide a surface for the brake pads or shoes to press against |

Credit: www.youtube.com

Hydraulic Brakes

Hydraulic brakes are a crucial component in the operation of semi trucks. The working principle of hydraulic brakes involves the transmission of force through a fluid-filled system. When the brake pedal is pressed, the force is transmitted to the brakes through hydraulic fluid. This force then activates the brake mechanisms, leading to the slowing or stopping of the vehicle. The components of a hydraulic brake system include a master cylinder, brake lines, calipers, and brake pads. Each of these elements plays a vital role in ensuring the effective functioning of the brakes, allowing for safe and reliable operations of semi trucks on the road.

Dual Brakes

Dual Brakes

The advantages of a dual brake system in semi trucks are immense. Dual brakes provide enhanced safety and control, as they work together to distribute the braking force evenly across all wheels. When braking, the dual system ensures equal pressure and helps to prevent skidding. By having two independent systems, the risk of a complete brake failure is significantly reduced. Dual brakes also provide redundancy, meaning that if one system fails, the other can still function effectively. This setup offers greater confidence to truck drivers, ensuring a safer driving experience.

Maintenance And Troubleshooting

Regular maintenance of semi truck brakes is crucial for ensuring their optimal performance and preventing potential accidents. Brakes should be inspected regularly to identify any signs of wear and tear, such as uneven pad wear, loose components, or leaks. Visual inspection of brake components, including the brake pads, rotors, calipers, and brake lines, is essential for detecting any issues. Additionally, the brake fluid levels should be checked and topped up if necessary, as low fluid levels can affect braking efficiency.

Despite regular maintenance, semi truck brakes can develop common issues that need troubleshooting. These may include squealing or grinding noises, vibrations, pulling to one side, or a spongy brake pedal. If any of these symptoms are observed, immediate action should be taken to identify and rectify the underlying problem. Common troubleshooting tips for semi truck brakes include checking brake pads for excessive wear and replacing them if needed, inspecting brake rotors for warping or damage and resurfacing or replacing them as required, and checking the brake system for air bubbles or leaks and repairing or replacing any faulty components. Regular maintenance and timely troubleshooting can ensure that semi truck brakes are in top shape, promoting safety on the road.

Credit: knottbrake.com

Frequently Asked Questions On How Semi Truck Brakes Work

How Do Semi Truck Brakes Work?

Semi truck brakes work using air pressure to activate the brake shoes, which press against the brake drum to slow down or stop the truck. When the driver steps on the brake pedal, air pressure is released, causing the brake shoes to engage and slow down the truck.

What Are The Different Types Of Semi Truck Brakes?

The different types of semi truck brakes include air brakes, hydraulic brakes, and electric brakes. Air brakes are the most common and use air pressure to engage the brakes. Hydraulic brakes use hydraulic fluid to activate the brakes, while electric brakes use an electric signal to engage the brakes.

How Often Do Semi Truck Brakes Need To Be Replaced?

Semi truck brakes should be replaced as soon as they show signs of wear and tear, such as reduced brake performance or noise. It is recommended to have the brakes inspected regularly, typically every 25,000 miles, to ensure they are in good working condition.

Regular maintenance and inspections can help prevent brake failure on the road.

Why Is It Important To Maintain Semi Truck Brakes?

Maintaining semi truck brakes is crucial for the safety of the driver and those on the road. Properly functioning brakes ensure that the truck can stop or slow down in a safe and timely manner, preventing accidents. Regular maintenance and inspections can catch any issues before they become major problems, reducing the risk of brake failure.

Conclusion

Semi truck brakes function as a crucial safety feature that should never be taken for granted. Understanding how these brakes work can help drivers and mechanics ensure their efficient functioning on the road. By applying the principles of friction and hydraulic pressure, semi truck brakes effectively slow down and stop heavy vehicles, preventing accidents and preserving the well-being of everyone on the road.

Keeping the brakes properly maintained and understanding their functionality is essential for the safety and smooth operation of semi trucks.