Semi truck engines work by converting fuel into energy through combustion, powering the vehicle’s movement. Semi truck engines play a vital role in the functioning and performance of these heavy-duty vehicles.

By converting fuel into energy through combustion, these engines provide the necessary power to move the truck and perform various tasks efficiently. Understanding how these engines work is crucial for truck operators and enthusiasts alike. We will delve into the inner workings of semi truck engines, exploring the processes and components that make them function effectively.

We will discuss key aspects such as combustion, fuel injection, air intake, and exhaust systems, providing a comprehensive overview of the engine’s operation. So, let’s dive in and explore the fascinating world of semi truck engines.

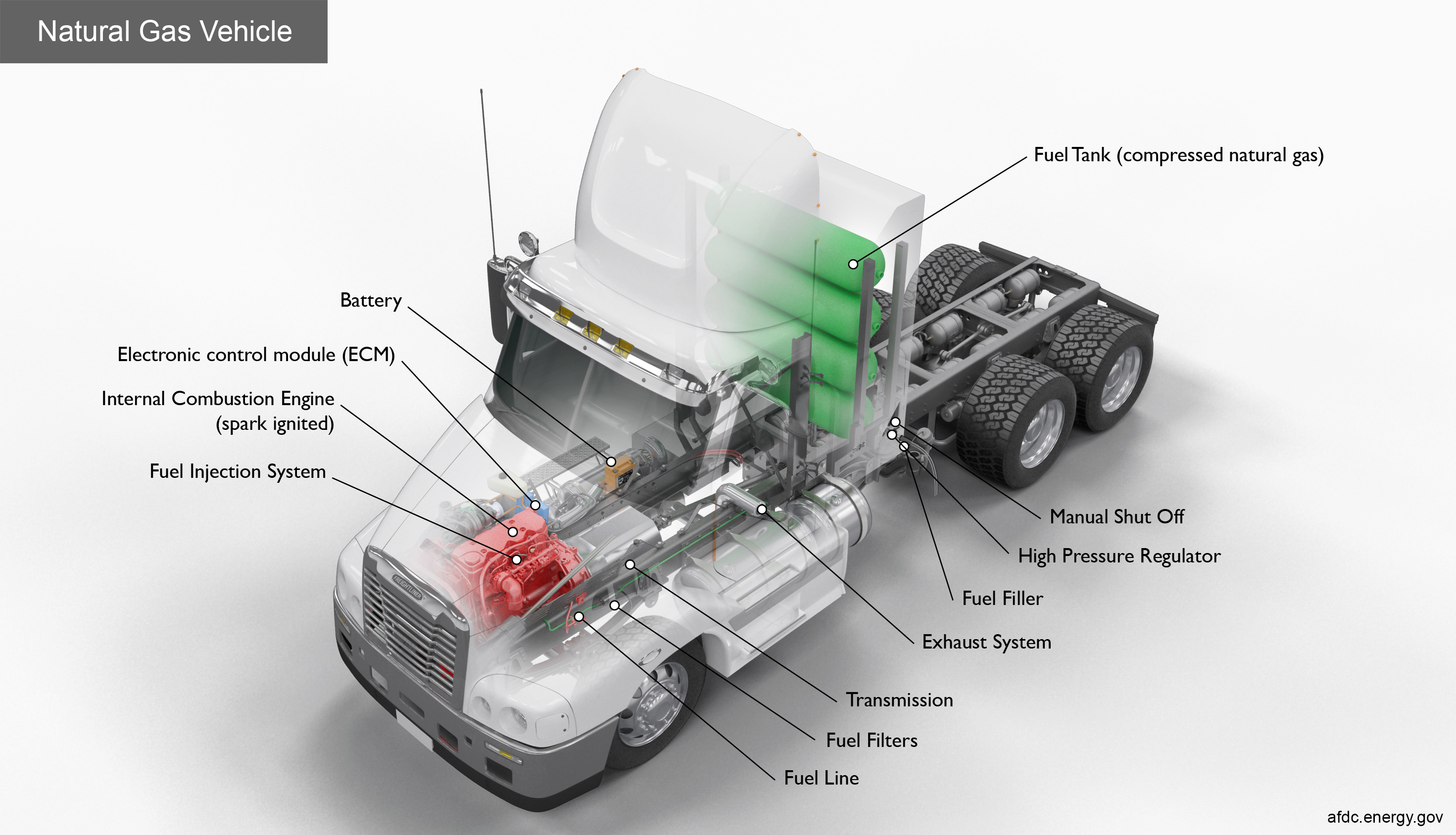

Credit: afdc.energy.gov

Navigate As You Want:

The Basics Of Semi Truck Engines

The basics of semi truck engines are quite fascinating. These powerful machines come in different types such as diesel, gasoline, and natural gas engines. Each type operates in a slightly different manner, but they all serve a common purpose – to provide the necessary power to move the truck on the road.

Diesel engines, for example, are commonly used in semi trucks due to their fuel efficiency and durability. They work by compressing air within the cylinders, which ignites the fuel when injected. This combustion process generates power that drives the truck forward.

Gasoline engines, on the other hand, rely on a spark plug to ignite a mixture of air and fuel. They are less common in semi trucks as they tend to consume more fuel and have lower torque compared to diesel engines.

Additionally, natural gas engines are gaining popularity in the trucking industry for their lower emissions. These engines use compressed natural gas or liquefied natural gas as fuel, which is ignited using a spark plug.

In conclusion, the function of semi truck engines is to convert the energy from fuel combustion into mechanical work, allowing the truck to move. Each type of engine has its own distinctive characteristics, and it is essential for truck drivers and mechanics to understand how they operate to ensure optimal performance and efficiency.

Credit: m.youtube.com

Components Of A Semi Truck Engine

The cylinder block is an essential component of a semi truck engine. It houses the cylinders where the combustion process takes place. Pistons and connecting rods are responsible for converting the force from the combustion into linear motion. They transfer that force to the crankshaft which converts it into rotational motion. The cylinder head sits on top of the cylinder block, sealing the combustion chamber and housing the valves. Valves control the flow of air and fuel into the cylinder and the exhaust gases out. The camshaft, located in the cylinder head, controls the opening and closing of the valves, ensuring proper timing and operation.

Working Of A Semi Truck Engine

The intake stroke of a semi truck engine draws in air and fuel into the combustion chamber. During the compression stroke, the mixture is compressed, which increases its temperature and pressure. This creates the ideal conditions for combustion. Next, the combustion stroke takes place, where the spark plug ignites the air and fuel mixture, resulting in a controlled explosion. This explosion forces the piston down, which generates power. Lastly, the exhaust stroke releases the burnt gases from the combustion chamber through the exhaust valve. The process then repeats to power the semi truck forward.

| Stroke | Description |

|---|---|

| Intake | Draws in air and fuel into the combustion chamber |

| Compression | Compresses the mixture, increasing its temperature and pressure |

| Combustion | Ignites the mixture, resulting in a controlled explosion |

| Exhaust | Releases the burnt gases from the combustion chamber |

Efficiency And Power Of Semi Truck Engines

Semi truck engines are designed for efficiency and power. Turbocharging technology is used to optimize the engine’s performance by increasing air intake. Direct injection allows fuel to be sprayed directly into the combustion chamber, enhancing fuel efficiency and power output. Cylinder deactivation further enhances fuel efficiency by shutting down specific cylinders when they are not needed, reducing fuel consumption. These advanced technologies work together to ensure that semi truck engines deliver optimal performance while maximizing fuel efficiency.

Credit: www.smart-trucking.com

Frequently Asked Questions On How Semi Truck Engines Work

How Do Semi Truck Engines Work?

Semi truck engines work by burning diesel fuel in the combustion chamber to create energy. This energy is then used to power the vehicle and its components, such as the transmission, wheels, and accessories.

What Is The Role Of Turbochargers In Semi Truck Engines?

Turbochargers help to increase the power and efficiency of semi truck engines by compressing air and forcing it into the combustion chamber. This results in more fuel being burned and greater energy output, allowing the truck to carry heavier loads and perform better on inclines.

Why Are Diesel Engines Commonly Used In Semi Trucks?

Diesel engines are preferred in semi trucks due to their higher torque output, better fuel efficiency, and longer lifespan compared to gasoline engines. These qualities make diesel engines well-suited for the demanding, long-haul nature of semi truck operations.

How Are Semi Truck Engines Maintained?

Semi truck engines are maintained through regular oil changes, filter replacements, and checks of the cooling and fuel systems. Additionally, tune-ups, inspections, and repairs by qualified technicians help ensure optimal engine performance and longevity.

Conclusion

Understanding how semi-truck engines work is crucial for optimizing their performance and maintaining their longevity. By learning about the intricate processes involved, truck drivers and mechanics can make informed decisions to ensure efficient fuel consumption and reduce environmental impact. Armed with this knowledge, they can keep their engines running smoothly and safely for years to come.