To test the tractor protection valve, remove the gladhands and set them on the deck, then listen for air exhausting from the trailer service line with the trailer supply valve closed, the trailer service line disconnected, and the service brakes applied. If air is exhausting from the trailer service line, the tractor protection valve is defective.

Testing the tractor protection valve is an essential part of ensuring the safety and proper functioning of a tractor’s air brake system. A defective tractor protection valve can lead to a loss of control and compromise the overall braking performance.

To avoid such risks, it is crucial to conduct regular tests to identify any faults or issues with the tractor protection valve. This article provides insights into how to properly test the tractor protection valve, ensuring optimal safety and functionality of the tractor’s air brake system. By following the step-by-step instructions, you can diagnose and rectify any problems with the tractor protection valve promptly, promoting safer and more efficient tractor operation.

Credit: www.smartdrivetest.com

Navigate As You Want:

How Tractor Protection Valve Works

To test the tractor protection valve, listen for air exhausting from the trailer service line with the trailer supply valve closed, the trailer service line disconnected, and the service brakes applied. This ensures the tractor protection valve is functioning properly in allowing air out of the trailer emergency line when closed.

| Tractor Protection Valve Works: A tractor protection valve crucial in the air brake system prevents air from escaping the tractor. It also activates the trailer emergency brakes in case of a separation. |

| Key role of Tractor Protection Valve: It maintains air in the tractor, preventing trailer brakes from locking up and providing braking control. |

| Consequences of malfunction: If the tractor protection valve malfunctions, it can lead to loss of control, potential accidents, and brake system failure. |

Credit: m.youtube.com

Testing Procedure

Testing Procedure:

- Make a service brake application to activate the Tractor Protection Valve.

- Perform a trailer air supply shutoff test. Ensure the air supply to the trailer is cut off.

- Test the air supply valve. Check if it closes properly when the trailer air supply is cut off.

- Disconnect the trailer and listen for any air exhausting from the trailer emergency line.

- Inspect the tractor protection valve by visually checking for any signs of damage or leakage.

Signs indicating a defective Tractor Protection Valve:

- Loss of air pressure in the trailer emergency line.

- Inability to disconnect the trailer.

- Unusual noises coming from the tractor protection valve.

- Visible leaks or damage on the valve.

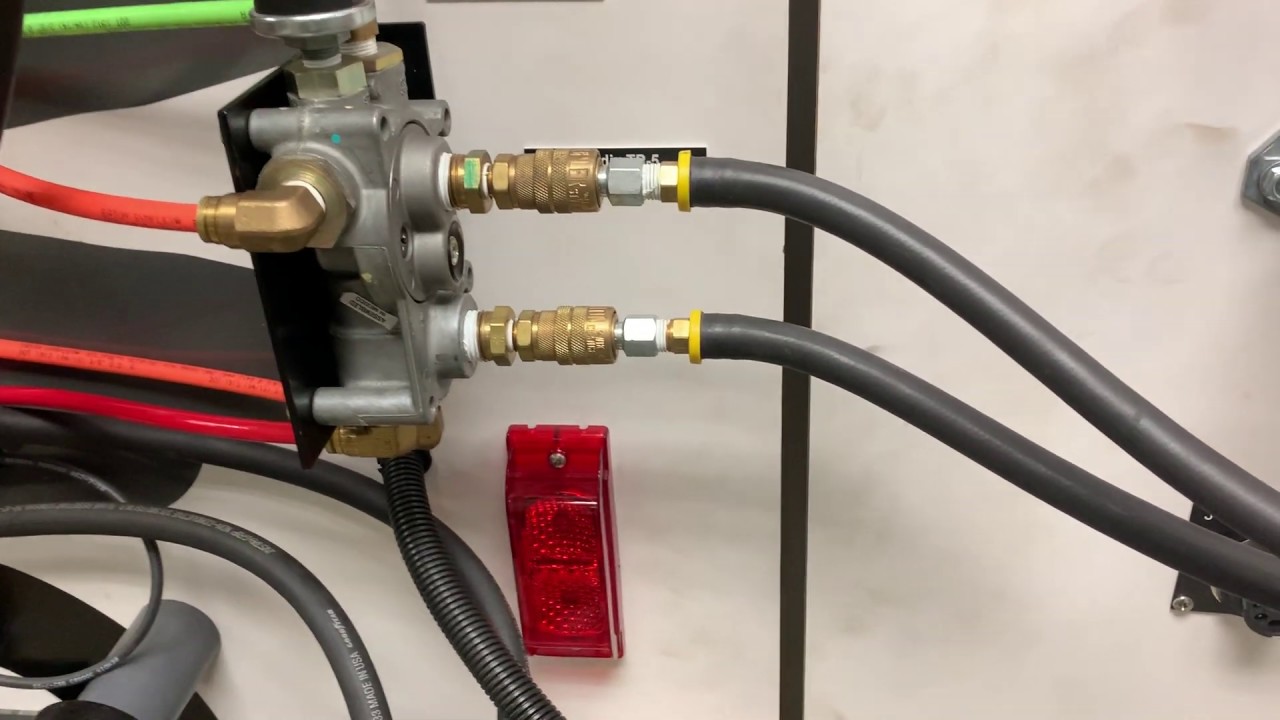

Tools And Equipment Required

To test the tractor protection valve, you will need an air gauge, a service brake application, a trailer air supply shutoff, an air supply valve, and a trailer. When conducting the test, listen for air exhausting from the trailer service line with the trailer supply valve closed, the trailer service line disconnected, and the service brakes applied.

Essential Tools For Accurate Testing

- Safety goggles

- Wrench set

- Pressure gauge

- Blow gun with air compressor

Safety Precautions During Testing

- Ensure the tractor is on a level surface

- Wear appropriate safety gear, including gloves and safety goggles

- Disconnect power source to avoid any accidental engagement

- Follow manufacturer’s instructions for proper usage of testing equipment

- Perform the tests in a well-ventilated area

- Keep bystanders at a safe distance from the testing area

- Inspect all equipment for any damage or defects before use

- Report any issues or concerns to a qualified professional

Credit: www.smartdrivetest.com

Top Tips For Maintenance

To test your tractor protection valve, start by making a service brake application and then performing a trailer air supply shutoff test. Next, test the air supply valve and the trailer air supply valve, followed by disconnecting the trailer for further inspection.

Finish by checking the trailer brakes thoroughly at the end of the process.

| Top Tips for Maintenance |

| Regular maintenance helps prevent Tractor Protection Valve issues. Ensure to check for leaks and proper functioning regularly. |

| When troubleshooting common problems, focus on identifying any unusual noises or air leaks in the system. Properly test and inspect the tractor protection valve for any faults or malfunctions. |

Frequently Asked Questions For How To Test Tractor Protection Valve

When Should Tractor Protection Valve Pop?

The tractor protection valve should pop when the air pressure in the trailer emergency line drops below a certain level, indicating a loss of air supply.

How Does A Tractor Protection Valve Work?

The tractor protection valve stops air from leaving the tractor and releases air from the trailer emergency line. This activates the trailer emergency brakes, potentially causing loss of control. Test the valve by closing the trailer supply valve, disconnecting the trailer service line, and applying the service brakes to listen for air exhaust.

What Happens When The Tractor Protection Valve Is Closed?

When the tractor protection valve is closed, it prevents air from leaving the tractor, activating the trailer emergency brakes. This can lead to a loss of control.

How Do You Test The Tractor Protection Valve Quizlet?

To test the tractor protection valve, apply the service brakes and close the trailer supply valve. Listen for air exhausting from the trailer service line. If air is released, the tractor protection valve is faulty. Smart Drive Test provides a video demonstration of this process.

Conclusion

As you wrap up testing the tractor protection valve, remember the importance of safety and precision. Ensuring proper functionality can prevent accidents and maintain smooth operations. Keep testing procedures in your routine maintenance to guarantee optimal performance and peace of mind.