If your semi-truck isn’t building air pressure, check for leaks in the air system and the air compressor’s functionality. Proper maintenance and regular checks on the air system can help prevent issues With a semi truck’s air brake system.

Neglecting to address low air pressure can cause safety hazards, violating regulations, and result in expensive repairs. Here are some common reasons why a semi-truck may not be building air pressure, and measures to take to address the issue and maintain a safe and reliable air brake system.

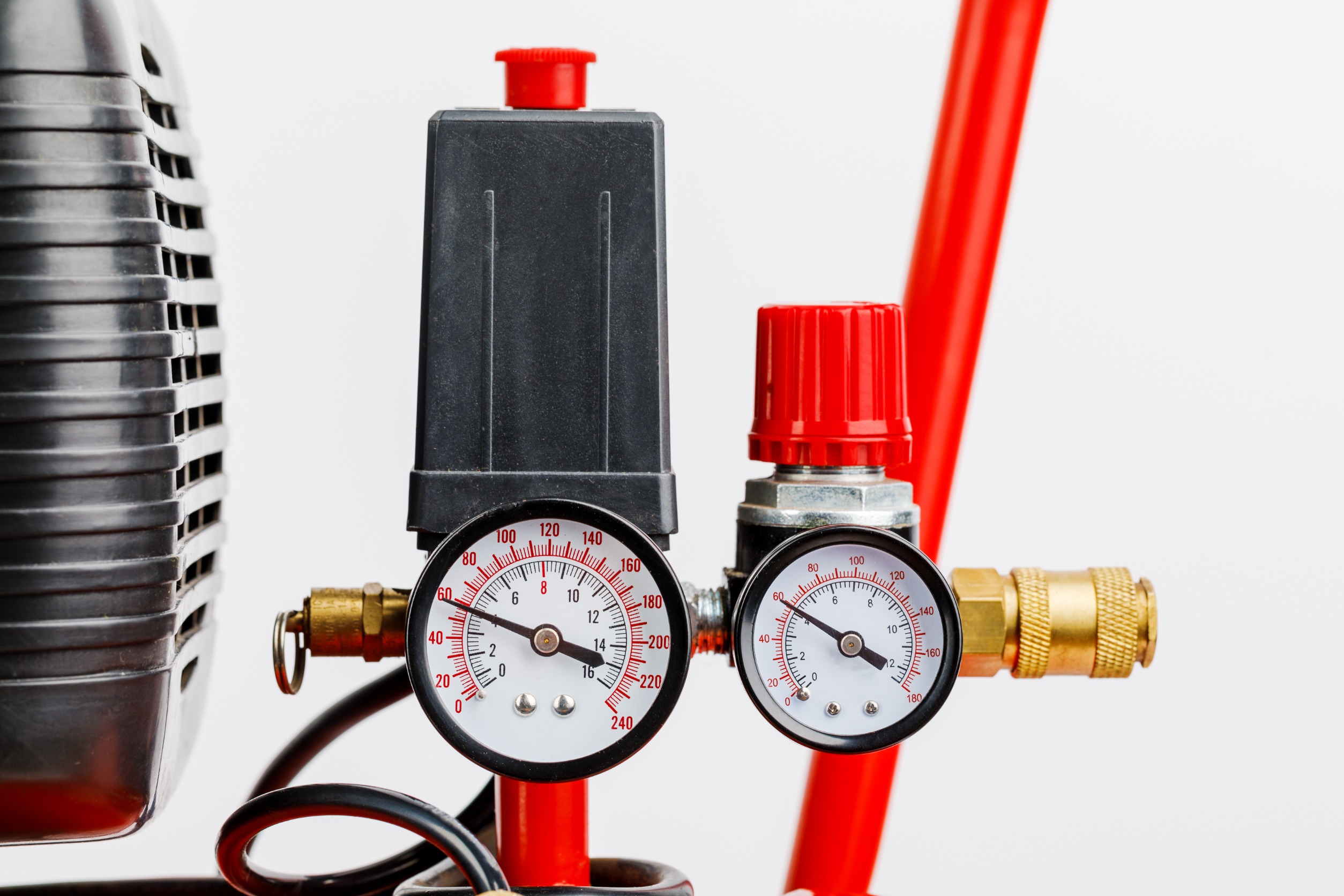

Credit: www.mobilesemitruckrepairlv.com

Navigate As You Want:

Common Causes Of Air Pressure Issues

Semi trucks experiencing air pressure issues can be attributed to various common causes. One possible cause is a faulty air compressor, which may fail to generate enough pressure to build air in the system. Another potential culprit is leaking air lines, where air escapes and prevents the proper pressure build-up. Additionally, a malfunctioning pressure regulator can also lead to air pressure problems. Identifying the cause of the issue is crucial to resolving the problem and ensuring the smooth operation of the semi truck. A thorough inspection of the air compressor, air lines, and pressure regulator is necessary to identify and address the specific problem. Prompt repairs or replacements may be required to restore proper air pressure and maintain the truck’s performance and safety.

Signs And Symptoms Of Air Pressure Problems

Low Air Pressure Warning: One of the signs of air pressure problems in a semi truck is the activation of the low air pressure warning light on the dashboard. This signifies that the air pressure in the system is below the recommended level. It is important to address this issue immediately to prevent further complications.

Ineffective Brakes: Another symptom of air pressure problems in a semi truck is ineffective brakes. Low air pressure can cause the brakes to become less responsive, leading to longer stopping distances and increased risk of accidents. This poses a serious safety concern and should be resolved as soon as possible.

Difficulty Shifting Gears: In addition to the above, difficulty shifting gears can also indicate air pressure problems in a semi truck. Insufficient air pressure can make it challenging to engage gears properly, affecting the vehicle’s performance and drivability. This issue warrants prompt attention to avoid further mechanical issues.

Troubleshooting Steps For Air Pressure Problems

Inspecting the Air Compressor: Start by inspecting the air compressor for any visible damage or leaks. Look for worn-out components or loose connections that could affect air pressure.

Checking for Air Leaks: Carefully examine the entire air system for any signs of air leaks. Common areas to check include air lines, fittings, valves, and the air dryer for any potential leaks.

Testing the Pressure Regulator: Use a pressure gauge to test the pressure regulator and ensure it is operating within the recommended range. Adjust or replace the regulator if it is not maintaining the correct pressure.

Credit: www.teamaircenter.com

Preventive Maintenance For Maintaining Proper Air Pressure

Semi trucks not building enough air pressure can lead to serious safety concerns. Regular air system inspections are crucial to ensure optimal performance. Identifying worn-out components is important as they can cause air leakage and ultimately affect the pressure buildup. Replacing these worn-out components promptly will prevent any further issues. Additionally, proper lubrication of the air compressor is essential to maintain its efficiency and prevent overheating. Regularly checking the oil level and using the recommended lubricants will aid in this process.

By prioritizing preventive maintenance and timely inspections, semi truck owners can prevent air pressure issues and ensure the safety of both the vehicle and its occupants.

Seeking Professional Help

If you are experiencing issues with your semi truck’s air pressure, it is advisable to consult a technician for assistance. A qualified professional can accurately diagnose the problem and provide the necessary repairs and solutions. Instead of attempting to fix it yourself or rely on trial and error methods, visiting a service center is a more reliable option. Technicians have the knowledge, experience, and access to specialized equipment to efficiently troubleshoot and resolve air pressure-related issues in semi trucks. Their expertise ensures a thorough evaluation of the system, addressing any potential underlying causes, and ensuring the problem is resolved effectively. By seeking professional help, you can save valuable time and effort, prevent further damage, and ensure your semi truck operates optimally for improved safety and performance.

Credit: m.youtube.com

Frequently Asked Questions Of Semi Truck Won’t Build Air Pressure

How Do I Know If My Semi Truck Won’t Build Air Pressure?

If your semi truck is taking longer than usual to build air pressure or if it’s not building air pressure at all, you may notice warning lights on the dashboard or hear abnormal noises from the air compressor. Additionally, the air pressure gauge may not reach the desired levels.

It is crucial to address this issue promptly to ensure the safe operation of your truck.

What Are The Possible Causes For A Semi Truck Not Building Air Pressure?

There are several potential causes for a semi truck not building air pressure. It could be due to a malfunctioning air compressor, leaky hoses or fittings, a faulty air governor, or a defective air dryer. Other possible causes include a blocked air filter or a problem with the pressure relief valve.

It is best to have a professional diagnose and repair the issue promptly.

How Can I Troubleshoot My Semi Truck Air Pressure Problem?

To troubleshoot a semi truck air pressure problem, start by checking for any visible air leaks in the system, including hoses, fittings, and couplings. Inspect the air compressor and air governor for any signs of damage or malfunction. Ensure that the air filter is clean and not clogged.

If the issue persists, consult a qualified technician to diagnose and fix the problem.

Why Is It Important To Address A Semi Truck Air Pressure Issue Promptly?

Addressing a semi truck air pressure issue promptly is vital for the safe operation of the vehicle. Insufficient air pressure can affect the braking system, causing longer stopping distances and potentially leading to accidents. It can also impact the truck’s performance and fuel efficiency.

Regular maintenance and immediate repair of air pressure problems are crucial for ensuring the truck’s optimal performance and the safety of the driver and other road users.

Conclusion

Troubleshooting air pressure issues in a semi-truck requires a systematic approach and careful attention to detail. By conducting regular inspections, maintaining the air system components, and addressing any potential leaks or malfunctions promptly, you can ensure the consistent build-up of air pressure within your truck.

Remember, a well-functioning air system is crucial for safe and efficient operations on the road. Stay proactive and keep your truck running smoothly.