Semi truck transmissions are not synchronized because it allows for easy shifting of heavy loads and offers better control during towing and off-road conditions. This design helps in reducing wear and tear on the transmission components and improves the truck’s overall reliability and efficiency.

Semi truck transmissions are not synchronized because it allows for easy shifting of heavy loads and offers better control during towing and off-road conditions. This design helps in reducing wear and tear on the transmission components and improves the truck’s overall reliability and efficiency.

This unique feature also contributes to better fuel economy and longer transmission life, making semi-truck transmissions highly suitable for the demands of commercial hauling and long-distance transportation. Their non-synchronized nature provides superior torque multiplication and allows the driver to drive comfortably in challenging terrains. This characteristic is a key factor in optimizing the performance and durability of semi-truck transmissions, enhancing their ability to meet the diverse needs of the trucking industry.

Navigate As You Want:

- The Basics Of Semi Truck Transmissions

- The Role Of Synchronization In Transmissions

- Reasons For Non-synchronization In Semi Truck Transmissions

- Advantages Of Non-synchronized Transmissions In Semi Trucks

- Challenges Faced By Drivers And Tips For Driving Non-synchronized Transmissions

- Frequently Asked Questions On Why Are Semi Truck Transmissions Not Synchronized

- Conclusion

The Basics Of Semi Truck Transmissions

The importance of transmissions in semi trucks cannot be overstated. Semi truck transmissions are specifically designed to handle the heavy loads and long distances that these vehicles are meant to travel. Without a properly functioning transmission, a semi truck would not be able to operate efficiently and effectively.

Semi truck transmissions come in different types, depending on the specific needs and requirements of the truck. The most common types include manual, automatic, and automated manual transmissions. Each type has its own set of advantages and disadvantages, but all serve the same purpose of transferring the engine’s power to the wheels.

One key difference between semi truck transmissions and those found in passenger vehicles is that semi truck transmissions are not synchronized. This means that gears must be shifted carefully and accurately to avoid grinding or damaging the transmission. While this can be more challenging for drivers, it allows for greater control and efficiency when hauling heavy loads.

Understanding the basics of semi truck transmissions is essential for anyone involved in the trucking industry. It is important to choose the right type of transmission for the specific needs of the truck and to properly maintain and care for it. By doing so, drivers can ensure their trucks operate smoothly and efficiently for years to come.

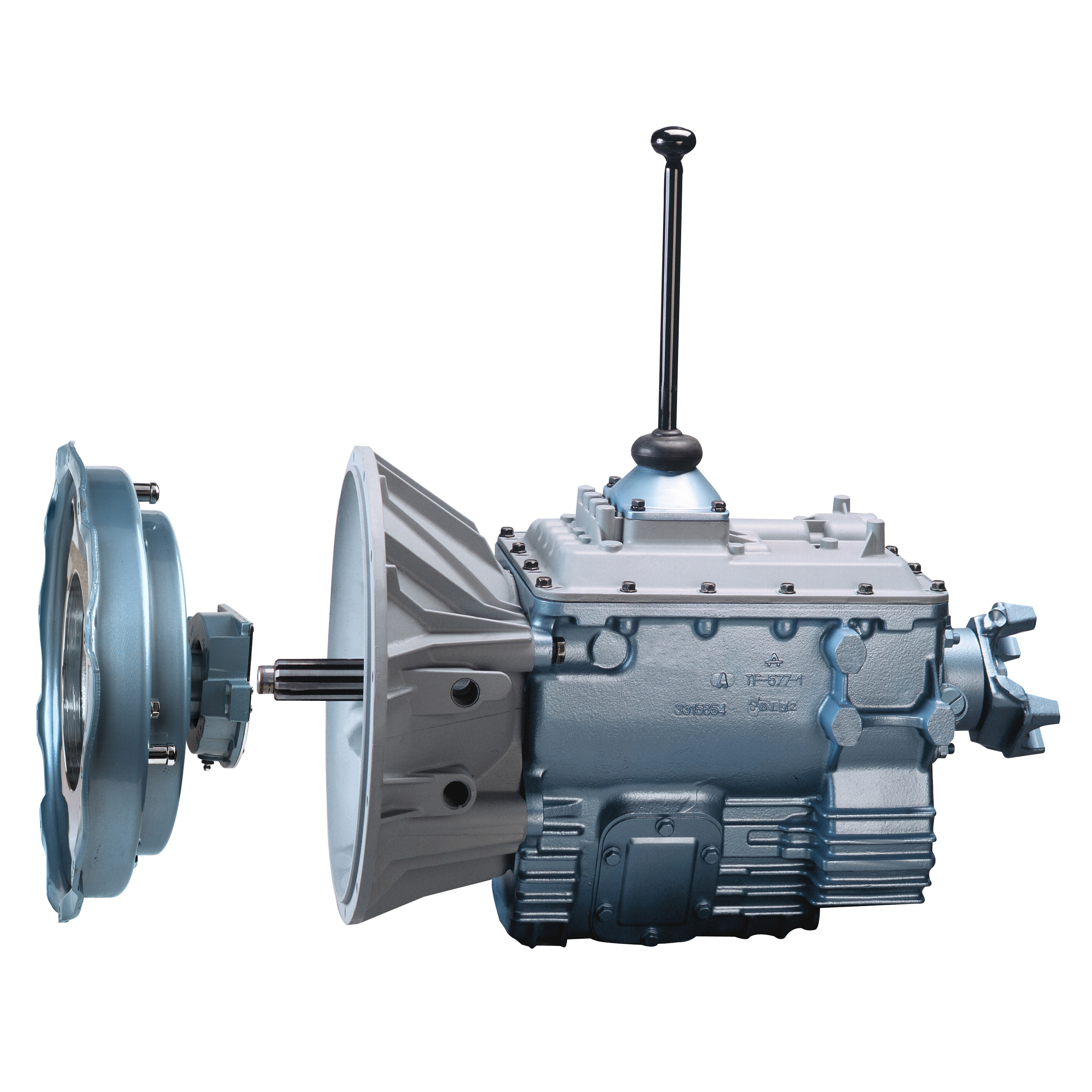

Credit: www.eaton.com

The Role Of Synchronization In Transmissions

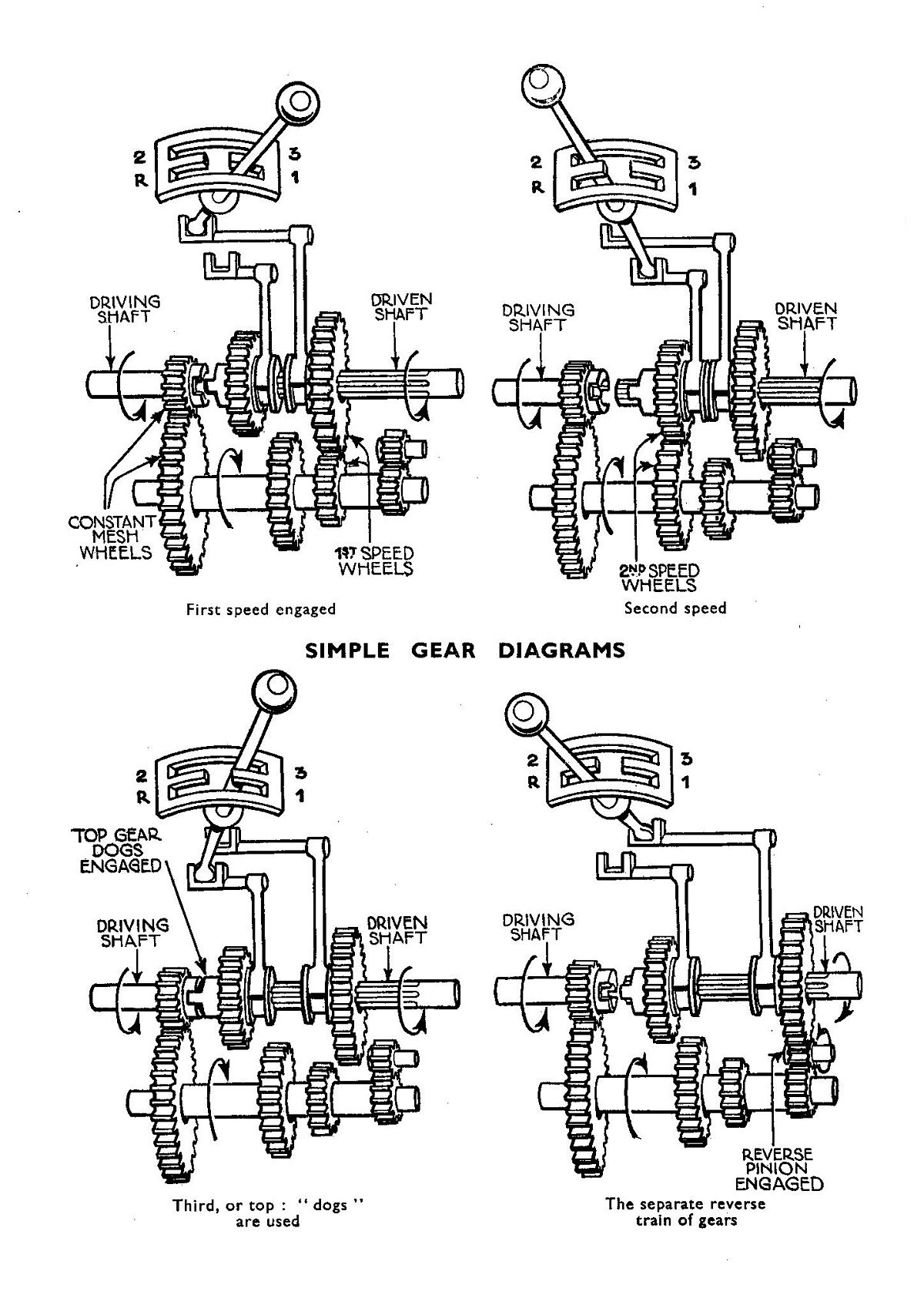

Semi truck transmissions are not synchronized due to the unique requirements of large commercial vehicles. Synchronization in transmissions involves the alignment of gears to enable smooth and seamless shifting. This precision is not found in semi truck transmissions, which operate using unsynchronized gear systems. As a result, the shifting process is more challenging and requires greater skill from the driver.

Reasons For Non-synchronization In Semi Truck Transmissions

Semi truck transmissions are not synchronized due to several reasons:

- Cost considerations: Synchronized transmissions are more costly to produce and maintain for heavy-duty vehicles.

- High torque requirements: Non-synchronized transmissions can handle the high torque produced by semi trucks more effectively.

- Efficiency and power considerations: Non-synchronized transmissions provide better efficiency and power delivery for semi truck operations.

Credit: en.wikipedia.org

Advantages Of Non-synchronized Transmissions In Semi Trucks

Non-synchronized transmissions in semi trucks offer several advantages over synchronized transmissions. Firstly, they provide better control over gear selection, allowing drivers to choose the appropriate gears for specific driving conditions. This helps in maintaining optimal performance and fuel efficiency. Reduced shifting effort is another benefit of non-synchronized transmissions. As the gears do not have to synchronize, the driver experiences less resistance when changing gears, resulting in smoother gear shifts. Finally, non-synchronized transmissions are known for their increased durability and reliability. The absence of synchronizer rings reduces wear and tear on the transmission, leading to longer-lasting and more dependable performance.

Challenges Faced By Drivers And Tips For Driving Non-synchronized Transmissions

Semi truck transmissions are not synchronized, which poses unique challenges for drivers. Understanding double clutching is essential to successfully drive these non-synchronized transmissions. Double clutching involves shifting gears by first pressing the clutch to disengage the current gear, then releasing the clutch while in neutral, and finally engaging the next gear. By double clutching, drivers can smoothly transition between gears and prevent grinding or damaging the transmission.

Another skill to master is RPM matching. This process involves adjusting the engine speed to match the rotational speed of the transmission, ensuring a seamless gear shift. RPM matching requires practice and coordination, but it can greatly improve the overall driving experience with non-synchronized transmissions.

To achieve the smoothest gear shifts, here are a few tips to keep in mind:

- Practice shifting gears in an open area with little traffic.

- Listen to the sound of the engine and pay attention to the feel of the transmission.

- Remember to fully engage the clutch before attempting to shift gears.

- Gradually release the clutch while applying throttle to smoothly engage the next gear.

By following these tips and refining the necessary skills, drivers can navigate the challenges of non-synchronized transmissions with confidence and efficiency.

Credit: salineauto.com

Frequently Asked Questions On Why Are Semi Truck Transmissions Not Synchronized

Why Are Semi Truck Transmissions Not Synchronized?

Semi truck transmissions are not synchronized because they need to handle heavy loads and provide maximum torque. This allows for smoother gear shifts and prevents damage to the transmission components. With unsynchronized transmissions, the driver must match the truck’s speed to engage the correct gear, resulting in better control and longevity of the transmission.

How Do Unsynchronized Transmissions Work In Semi Trucks?

In semi trucks with unsynchronized transmissions, the gears on the main shaft are constantly rotating, even when the transmission is in neutral. The driver must match the engine’s output speed with the truck’s speed to engage the desired gear. This requires expert timing and skill, as shifting at the wrong time can result in gear grinding or premature wear.

Are Unsynchronized Transmissions Only Used In Semi Trucks?

Unsynchronized transmissions are commonly used in large commercial vehicles like semi trucks because of their ability to handle heavy loads and provide maximum torque. However, they can also be found in other industrial vehicles such as buses, construction equipment, and military vehicles.

The unsynchronized design allows for better control and durability in demanding conditions.

Conclusion

Semi truck transmissions are not synchronized for a reason: to enhance performance and achieve optimal power transfer. By using unsynchronized transmissions, trucks can handle heavy loads more efficiently, prevent gear grinding, and allow for smoother gear shifting. Understanding the mechanics behind this design empowers drivers to make informed decisions and ensure a successful and safe driving experience.

Embracing the significance of unsynchronized transmissions unlocks the potential for improved efficiency in the trucking industry.