Truck drivers don’t use clutch due to the widespread use of automatic transmissions, which require less manual shifting. This saves time and reduces driver fatigue.

Truck drivers appreciate the convenience and efficiency of automatic transmissions, allowing them to focus on driving safely and reaching their destinations promptly. The advancement of technology in the trucking industry has greatly influenced the shift away from manual transmission. Automatic transmissions provide smoother gear changes and improved fuel efficiency, leading to increased productivity for truck drivers.

Additionally, the reduced wear and tear on the vehicle’s components contribute to cost savings in the long run. Overall, the shift towards automatic transmissions has revolutionized the way truck drivers operate on the road.

Credit: www.quora.com

Navigate As You Want:

- 1. The Evolution Of Truck Transmissions

- 2. Understanding Clutchless Shifting

- 3. The Role Of Synchronizers In Modern Truck Transmissions

- 4. Benefits Of Using Clutchless Shifting For Truck Drivers

- 5. Training And Safety Considerations For Clutchless Shifting

- Frequently Asked Questions Of Why Don’t Truck Drivers Use Clutch

- Conclusion

1. The Evolution Of Truck Transmissions

Manual Transmissions in Early Trucks: In the early days, truck drivers primarily used manual transmissions, which required them to use the clutch for shifting gears.

Introduction of Automated Manual Transmissions: With technological advancements, automated manual transmissions were introduced, which eliminated the need for constant clutch usage.

Advantages of Automated Manual Transmissions: Automated manual transmissions offer benefits such as smoother gear shifts, reduced driver fatigue, and improved fuel efficiency.

Credit: m.youtube.com

2. Understanding Clutchless Shifting

Truck drivers often opt for clutchless shifting, a technique that allows them to change gears without using the clutch. This method reduces wear and tear on the clutch system and improves overall fuel efficiency.

| Clutchless Shifting |

| Clutchless shifting is a technique used by some truck drivers. |

| It involves changing gears without using the clutch pedal. |

| How Clutchless Shifting Works |

| Truck drivers match engine speed to transmission speed for smooth gear changes. |

| Benefits of Clutchless Shifting |

| Clutchless shifting can reduce wear and tear on the clutch system. |

| It can also lead to faster gear changes and improved fuel efficiency. |

| Challenges and Limitations |

| Clutchless shifting requires skill and practice to avoid damaging the transmission. |

| Not all trucks are designed for clutchless shifting, limiting its widespread use. |

3. The Role Of Synchronizers In Modern Truck Transmissions

Truck drivers nowadays primarily use automatic transmissions due to synchronizers in modern trucks. Synchronizers facilitate smooth gear shifts without the need for clutch pedals. These devices are essential for improved fuel efficiency and driving comfort.

Synchronizers work by matching the speeds of different gears before engagement, ensuring a seamless transition and reducing wear on transmission components. Compared to manual transmissions that rely heavily on clutches, synchronizers provide quicker gear shifts and enhanced driving experience for truck drivers.

| 3.1 What Are Synchronizers? | Synchronizers are transmission components that aid in gear shifting by matching speeds of different gears. |

|---|---|

| 3.2 Synchronizers vs Clutches | Synchronizers eliminate the need for clutch engagement during gear shifts, unlike traditional manual transmissions. |

| 3.3 Improved Gear Shifting Efficiency | Synchronizers contribute to smoother gear shifts, reduced driver fatigue, and optimized fuel efficiency in modern trucks. |

4. Benefits Of Using Clutchless Shifting For Truck Drivers

Truck drivers can benefit from clutchless shifting techniques. This method reduces fatigue and improves comfort during long hours on the road. Clutchless shifting also allows for faster and smoother gear shifting, resulting in a more efficient driving experience. In addition, this approach can extend the life of the clutch, reducing maintenance costs for truck drivers over time.

5. Training And Safety Considerations For Clutchless Shifting

Truck drivers utilize clutchless shifting due to the efficiency and reduced wear on the transmission. Training and safety protocols are crucial for mastering this technique, as it requires precise timing and coordination for smooth gear changes, ensuring optimal performance and reducing mechanical strain on the vehicle.

| Proper Techniques for Clutchless Shifting | Importance of Skill Development | Potential Risks and How to Mitigate Them |

|---|---|---|

| Truck drivers often opt for clutchless shifting techniques to improve efficiency and reduce wear and tear on their vehicles. By eliminating the need to use the clutch pedal, drivers can shift gears smoothly and quickly, enhancing the overall driving experience. | Developing the skills necessary for clutchless shifting is crucial for truck drivers. Proper training and practice are needed to ensure drivers have a solid understanding of the technique and can execute it safely and effectively. This involves learning to match engine speed with transmission speed and mastering the timing required for smooth gear changes. | While clutchless shifting offers numerous benefits, it’s important to be aware of potential risks. Without proper technique and skill, drivers may experience transmission damage, increased fuel consumption, and decreased control over the vehicle. However, these risks can be mitigated with appropriate training, regular vehicle maintenance, and careful monitoring of gear selection and engine RPM. |

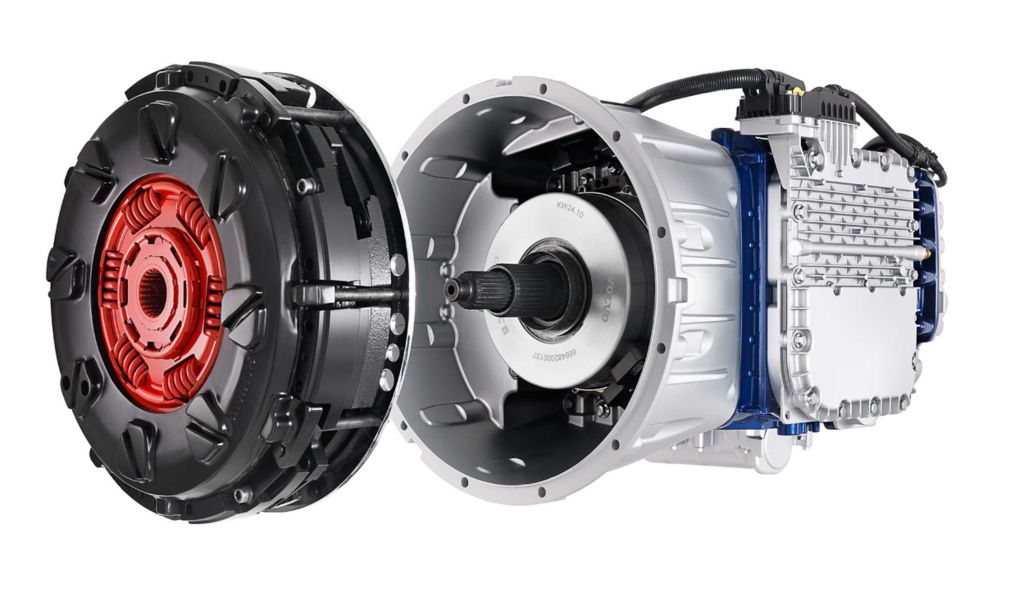

Credit: www.volvotrucks.com

Frequently Asked Questions Of Why Don’t Truck Drivers Use Clutch

Why Don’t Truck Drivers Use Clutch?

Truck drivers don’t use the clutch because most modern trucks have automated manual transmissions (AMTs). These AMTs use advanced technology to shift gears smoothly without the need for clutch operation. This makes driving easier and more efficient for truck drivers, saving them time and effort on the road.

How Do Automated Manual Transmissions Work?

Automated manual transmissions, or AMTs, work by using sensors and electronic controls to automate the process of shifting gears. When the system detects the need for a gear change, it automatically engages the clutch, shifts gears, and disengages the clutch without any input from the driver.

This allows truck drivers to focus on other aspects of driving, improving safety and efficiency.

Are There Any Advantages To Not Using The Clutch While Driving?

Yes, there are several advantages to not using the clutch while driving. First, it reduces fatigue for the driver, as they don’t have to constantly engage and disengage the clutch. Second, it improves fuel efficiency, as the automated shifting is optimized for optimal gear selection.

Finally, it increases safety, as automated manual transmissions ensure smoother gear changes and minimize the risk of stalling.

Conclusion

Truck drivers don’t use the clutch due to advances in technology and the efficiency of automatic transmissions. The modern trucking industry has shifted towards this method for improved performance and ease of use. As a result, truck drivers can navigate through different terrains seamlessly and efficiently without relying on the clutch.

This shift reflects the industry’s commitment to improving safety and productivity.