To check slack adjusters for CDL, conduct a visual inspection for wear and proper alignment of the brake chamber pushrod. Then, measure the pushrod stroke to ensure it falls within the specified range for adjustment.

Ensuring the proper functioning of slack adjusters is crucial for maintaining safe driving conditions. CDL holders should regularly inspect these components to prevent brake issues and potential accidents. By following the recommended guidelines for checking and adjusting slack adjusters, drivers can enhance the performance and reliability of their brake systems, contributing to overall road safety.

Proper maintenance of these critical components can also help drivers comply with regulatory standards, ensuring smooth operations and peace of mind while on the road.

Navigate As You Want:

Importance Of Checking Slack Adjusters

Slack adjusters are critical components of a commercial vehicle’s air brake system. They are responsible for maintaining the proper clearance between brake shoes and drums, ensuring efficient braking. Regular inspection of slack adjusters is crucial to prevent brake failure and ensure road safety. These components can wear out over time due to constant friction, leading to excessive brake shoe clearance or even brake system failure. It is essential to check slack adjusters for proper operation, wear, and tear regularly. This helps in identifying any issues early and addressing them before they escalate into more significant problems. The frequency of checking slack adjusters should be in line with the manufacturer’s recommendations, which typically suggest checking them during routine vehicle inspections or maintenance intervals.

Credit: www.smartdrivetest.com

Visual Inspection

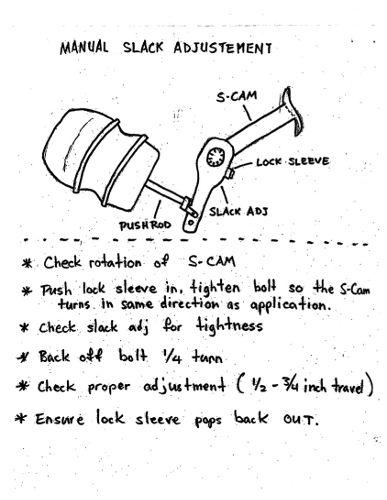

To check slack adjusters for CDL, conduct a visual inspection. Examine the adjusters for any signs of damage, corrosion, or excessive wear. Look for proper alignment and ensure that the adjusters are securely attached.

| Exterior examination: Look for any cracks or corrosion on the slack adjuster. |

| Interior examination: Check for any loose or missing components inside the slack adjuster. |

| Signs of wear and tear: Pay attention to any signs of excessive wear on the adjuster arm or markings on the adjuster body. |

Testing The Functionality

To check slack adjusters CDL, verify functionality by conducting inspections and testing for proper operation. Perform visual checks, such as assessing the push rod travel and slack adjuster positioning. Utilize a suitable testing tool to measure brake stroke and ensure compliance with CDL requirements.

| Testing the Functionality | |

| -Apply brakes to ensure proper movement | -Confirm pushrod travel meets required standards |

Credit: m.youtube.com

Maintenance And Repair

Maintenance and Repair: Checking slack adjusters is an essential part of maintaining the CDL. Lubrication of the slack adjusters should be done regularly to ensure smooth operation. Replacement of worn parts is necessary to prevent any malfunctions. Adjusting the slack adjusters should be done according to the manufacturer’s adjustment procedures to maintain the proper tension and functionality. Regular inspection and maintenance help in ensuring the safety and efficiency of the CDL system.

Compliance And Regulations

Ensuring compliance with regulations is crucial for checking slack adjusters for CDL. Regular inspections maintain safety and prevent violations. Stay informed to uphold standards effectively.

Checking slack adjusters for CDL compliance is crucial to ensure the safety of commercial vehicles. The Federal Motor Carrier Safety Regulations (FMCSRs) outline the standards and requirements that all commercial drivers must follow. These regulations cover various aspects such as vehicle maintenance, inspections, and driver responsibilities.

In addition to the FMCSRs, there may also be state-specific regulations that dictate additional guidelines and procedures for checking slack adjusters. It is important for drivers to be aware of and comply with these state-specific requirements to avoid penalties and ensure the safe operation of their vehicles.

Driver responsibilities include conducting routine inspections of slack adjusters and other brake components. Drivers should check for any signs of wear, damage, or improper adjustment. Regular maintenance and proper adjustment of slack adjusters are essential to prevent brake failure and maintain optimal braking performance.

Credit: www.smartdrivetest.com

Frequently Asked Questions Of How Can You Check Slack Adjusters Cdl

What Is A Slack Adjuster?

A slack adjuster is a crucial component of the braking system in commercial vehicles. It is responsible for maintaining the correct distance between the brake shoes and the brake drum. It helps to ensure proper braking performance and safety on the road.

How Do Slack Adjusters Work?

Slack adjusters work by transferring the force applied by the brake chamber to the brake shoes, causing them to press against the brake drum. This action creates friction, slowing down or stopping the vehicle. They automatically adjust to compensate for wear and tear, ensuring optimal braking efficiency.

Why Is It Important To Check Slack Adjusters?

Checking slack adjusters is vital to ensure the safe operation of your commercial vehicle. Over time, they can become maladjusted or worn out, leading to poor braking performance and increased stopping distances. Regular inspections and maintenance help prevent accidents caused by brake failure or inadequate braking power.

How Can You Check Slack Adjusters On A Cdl Vehicle?

To check slack adjusters on a CDL vehicle, you can visually inspect them for signs of damage, wear, or improper adjustment. Ensure the brake shoes are properly aligned with the brake drums. You can also apply force to the brake pedal while checking for any excessive or uneven movement of the slack adjusters.

Conclusion

Regular inspections and maintenance of slack adjusters are crucial for CDL holders. Proactively checking for excessive play or wear can help prevent brake malfunctions and ensure vehicle and road safety. By following these guidelines, you can effectively maintain your slack adjusters, comply with regulations, and contribute to a safer transportation environment.