To check slack adjusters for a CDL, ensure the vehicle is secured, locate the adjuster, and inspect for proper tension. Checking slack adjusters is crucial for safe vehicle operation and compliance with regulations.

By performing regular checks, drivers can ensure the brakes are functioning optimally, which is essential for road safety and overall vehicle performance. Following these steps can help CDL holders maintain their vehicles in top condition, reducing the risk of brake failure and ensuring smooth operation during their journeys.

Regular inspections of slack adjusters are a standard practice for responsible drivers who prioritize safety on the road and compliance with industry standards.

Credit: m.youtube.com

Navigate As You Want:

Step-by-step Guide To Checking Slack Adjusters

Preparation: Before checking slack adjusters, ensure the vehicle is parked on a level surface and the brakes are released. Wear appropriate safety gear and chock the wheels.

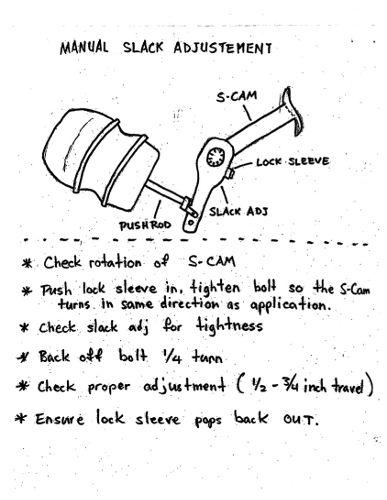

Visual Inspection: Inspect the slack adjusters for any signs of damage, wear, or corrosion. Check for excessive pushrod travel and make sure the clevis pins are secure.

Measurement: Using a suitable tool, measure the pushrod stroke to ensure it falls within the specified range. Refer to the vehicle’s manual for the correct measurement.

Adjustment: If the slack adjuster is out of the specified range, it may need adjustment. Follow the manufacturer’s guidelines to make the necessary adjustments.

Credit: www.smartdrivetest.com

Credit: www.smartdrivetest.com

Frequently Asked Questions On How To Check Slack Adjusters Cdl

How Do I Check Slack Adjusters For My Cdl?

To check the Slack Adjusters for your CDL, first, park your vehicle on a flat surface. Then, locate the adjuster near the brake drum and inspect it visually for any damage or wear. Next, measure the pushrod stroke using a brake stroke indicator to ensure it falls within the acceptable range.

Finally, test the brake’s performance by applying pressure on the pedal and observing the adjuster’s response.

Why Are Slack Adjusters Important For Cdl Holders?

Slack Adjusters are crucial for CDL holders because they play a vital role in maintaining the braking system’s efficiency and safety. These components help ensure proper brake application and prevent excessive wear on the braking components, promoting better vehicle control and reducing the risk of brake failure.

Regularly checking and adjusting Slack Adjusters is essential for a CDL holder’s safety and compliance with regulations.

What Causes Slack Adjusters To Malfunction?

Slack Adjusters can malfunction due to several reasons. Some common causes include improper lubrication, wear and tear from regular use, damage from debris or road hazards, and lack of regular maintenance. Additionally, incorrect installation or adjustment can lead to malfunctions.

It’s important to address any issues promptly and have professionals inspect and repair or replace faulty Slack Adjusters to prevent further damage and ensure safe operation.

Conclusion

Checking slack adjusters is crucial for CDL operators to ensure vehicle safety. Regular inspections help prevent brake failure and accidents. By following proper procedures, drivers can maintain their CDLs and keep the roads safe for everyone. Stay proactive in maintaining your vehicle to ensure a smooth and safe driving experience.