To check slack adjusters on air brakes, inspect brake camshaft lubrication, cam head, rollers, and friction blocks for wear. Replace worn parts as needed.

Maintaining proper lubrication and evaluating wear on key components ensures optimal performance and safety of air brake systems. Regular inspections and timely replacements help prevent potential brake failures, ensuring the overall functionality and effectiveness of the system. Proper maintenance of slack adjusters is essential for the safe operation of vehicles equipped with air brakes, and routine checks can help identify any issues before they escalate into more significant problems.

Staying vigilant in monitoring and addressing slack adjuster conditions is crucial for ensuring safe and reliable braking performance.

Credit: www.dnr.louisiana.gov

Navigate As You Want:

Methods Of Checking Slack Adjusters

One method of checking slack adjusters is through a visual inspection. During this process, you should inspect the brake camshaft and cam tube to ensure proper lubrication. Pay close attention to the cam head and rollers, looking for any signs of abnormal wear. Additionally, evaluate the friction blocks of the brakes for wear levels and cracks. If any issues are found, it is important to replace the friction blocks as necessary.

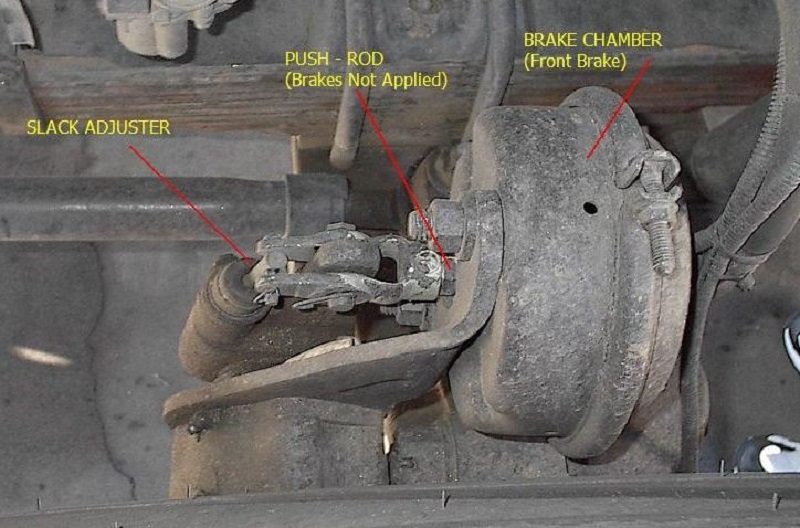

Another method you can use is the free and applied stroke test. Start by marking the push rod in line with the brake chamber and make a full brake application. Then, mark the push rod again. Measure the distance between the two marks to determine the length of push-rod travel or stroke. This test helps identify whether the slack adjuster is within the correct adjustment range.

The automatic slack adjuster check is another reliable method for checking air brake adjustment. This involves evaluating the brake pedal’s performance and checking for any uneven wear patterns on the brake shoes. If the brake pedal feels spongy or requires more effort to engage, it may indicate a failing slack adjuster. Examining the wear patterns on the brake shoes can also give you an idea of the adjuster’s condition.

Credit: carfromjapan.com

Manual Slack Adjuster Check

To manually check slack adjusters on air brakes, with service brakes in the released position, mark the push rod even with the brake chamber. Then, make a full brake application and remark the push rod. Measure between the two marks to determine the length of push-rod travel (stroke).

This method helps ensure air brake adjustment is properly maintained.

| Manual Slack Adjuster Check |

| – Marking the Push Rod: With brakes released, mark push rod by brake chamber. Apply brakes fully and mark again. Measure travel between marks. |

| – Measuring Push-Rod Travel: Determine stroke length by measuring the push-rod travel to ensure proper adjustment. |

Automatic Slack Adjuster Maintenance

To check slack adjusters:

- Ensure proper lubrication of brake camshaft and cam tube.

- Inspect cam head and rollers for abnormal wear.

- Evaluate friction blocks for wear and cracks, replace if needed.

Identifying Slack Adjuster Issues

Automatic slack adjusters play a critical role in the proper functioning of air brake systems.

One common issue to look out for is a spongy brake pedal. If you notice that the brake pedal feels soft or requires more effort to engage, it could be a sign of a failing slack adjuster.

Another indicator of slack adjuster problems is uneven brake wear. Take a look at the wear patterns on your brake shoes. If you notice significant differences in wear between the brakes on the same axle, it may be due to an issue with the slack adjuster.

Over-adjustment or under-adjustment are also potential issues to be aware of. If a slack adjuster is over-adjusted, it can cause premature wear and damage to the braking system. On the other hand, if it is under-adjusted, it can lead to reduced braking efficiency.

Regular inspection and maintenance of slack adjusters is crucial for ensuring the safety and effectiveness of air brakes. Check for proper lubrication, abnormal wear on the cam head and rollers, and the wear level and cracks on the friction blocks. Replace any components that are worn or damaged. By taking these steps, you can identify and address slack adjuster issues before they escalate into more significant problems.

Credit: m.youtube.com

Frequently Asked Questions For How To Check Slack Adjusters On Air Brakes

How Can You Check The Slack Adjusters?

To check the slack adjusters, inspect the brake camshaft, cam tube lubrication, and cam head and rollers for wear. Also, evaluate the friction blocks for wear and cracks, and replace if needed. Look for spongy brake pedals and uneven brake wear as signs of a failing slack adjuster.

How Do I Know If My Slack Adjuster Is Bad?

To check if your slack adjuster is bad, look for signs like a spongy brake pedal or uneven brake wear. If the brake pedal feels soft or requires more effort to engage, it could indicate a failing slack adjuster. Additionally, inspect the wear patterns on your brake shoes for any abnormalities.

Regular maintenance and inspection of the brake camshaft, cam tube, and friction blocks are also important.

How Do I Know If My Air Brakes Are Out Of Adjustment?

To check if your air brakes are out of adjustment, inspect the slack adjusters for proper lubrication and abnormal wear. Ensure the brake’s friction blocks are not worn or cracked. Look out for spongy brake pedals and uneven brake wear as signs of a bad slack adjuster.

What Is The Most Reliable Method Of Checking Air Brake Adjustment?

To check air brake adjustment, use the Applied Stroke Method to measure push rod travel accurately.

Conclusion

To ensure the proper functioning and safety of your air brakes, it is essential to regularly check the slack adjusters. By following the recommended methods of inspection, such as evaluating the brake’s friction blocks and checking for wear or cracks, you can identify any issues and take appropriate action.

Additionally, monitoring the performance of your air brakes, such as spongy brake pedals or uneven brake wear, can help you determine if there are problems with the slack adjusters. Remember, regular maintenance and inspection are crucial in keeping your air brakes in optimal condition.