To remove a slack adjuster, first, cut it apart if frozen on the shaft and a puller fails. Then replace it by pulling wheels and drum for manual adjusters.

A Haldex slack adjuster requires specific removal techniques, such as using a puller or cutting it apart if frozen. Identifying a failing slack adjuster involves symptoms like spongy brake pedals or uneven brake wear, necessitating prompt replacement. Following proper steps like dislodging fasteners, removing clevis and link pins, and installing a new adjuster ensures a functional air brake system.

Truckers may encounter challenges like stuck or frozen slack adjusters, requiring careful techniques for successful removal to maintain vehicle safety and efficiency.

Navigate As You Want:

Common Signs Of A Bad Slack Adjuster

Common signs of a bad slack adjuster include a spongy brake pedal and uneven brake wear. If the brake pedal feels soft or requires more effort to engage, it may indicate a failing slack adjuster. Additionally, inspecting the wear patterns on the brake shoes can help identify any uneven brake wear, which may be a result of a faulty slack adjuster. Understanding these warning signs is crucial for maintaining optimal brake performance and ensuring safe driving conditions.

Credit: m.youtube.com

Methods For Removing A Slack Adjuster

To remove a slack adjuster, first, dislodge the fastener like a snap ring or clip using snap-ring pliers or a screwdriver. Then, remove the clevis and link pins. If necessary, you may need to cut the S-cams to release the slack adjuster.

| Methods for Removing a Slack Adjuster |

| Using Snap-Ring Pliers or Screwdriver: |

| Most slack adjusters are held by a snap-ring or thin metal clip. Use snap-ring pliers or a screwdriver to dislodge the fastener. |

| Cutting it Apart: |

| If the adjuster is frozen on the shaft, consider using a puller. If that fails, cutting it apart might be necessary. |

| Using a Puller: |

| A puller designed for the application can be used to remove a stubborn or frozen slack adjuster from the shaft. |

Advice For Removing A Frozen Slack Adjuster

If you’re struggling to remove a frozen slack adjuster, consider using a specialized puller designed for this application. However, if that doesn’t work, cutting it apart may be necessary. Just remember, manual adjusters are inexpensive to replace.

| Advice for Removing a Frozen Slack Adjuster: |

| Invest in a puller designed for this application if the slack adjuster is frozen on the shaft. |

| Consider cutting it apart if the puller does not work as manual adjusters are cost-effective to replace. |

| Remember to remove the wheels and drum to replace the S Cam and shaft connected to the slack adjuster. |

| Consult online resources or videos for step-by-step guidance on removing and replacing slack adjusters in air brake systems. |

Credit: waterstorage.tpub.com

Tips For Replacing A Slack Adjuster

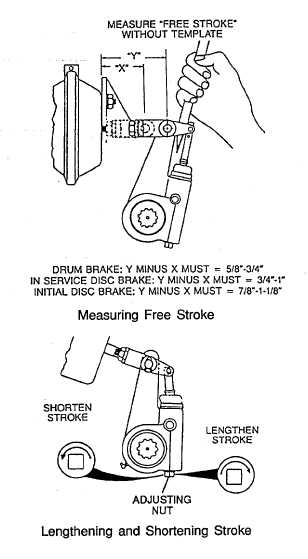

Measure Brake Stroke Length: Before replacing a slack adjuster, it’s essential to measure the brake stroke length to ensure that the new slack adjuster is properly adjusted.

Remove Snap Ring on Slack Adjuster: Using snap-ring pliers or a screwdriver, dislodge the fastener before proceeding to remove the clevis and link pins.

Remove Slack Adjuster from S-cam: After removing the snap ring, the old slack adjuster can be removed from the S-camshaft, allowing space for the installation of the new one.

Installing New Slack Adjuster: Once the old slack adjuster is removed, the new one can be installed in its place, ensuring that it is securely positioned.

Set Brake Adjustment: After installing the new slack adjuster, it’s important to set the brake adjustment to ensure optimal performance of the braking system.

Setting Slack Adjuster: Finally, ensure that the slack adjuster is correctly set to guarantee proper alignment and functionality within the braking system.

Credit: www.driverlogbooks.com

Frequently Asked Questions Of How To Remove Slack Adjuster

How Do I Remove A Frozen Slack Adjuster?

To remove a frozen slack adjuster, use a puller designed for this application. If it won’t budge, cut it apart as manual adjusters are inexpensive. The S-cam and shaft will need the wheels and drum pulled to replace it.

How Do You Remove A Haldex Slack Adjuster?

To remove a Haldex slack adjuster, cut it apart if frozen on the shaft for prompt removal. No need to worry about manual adjusters as they are inexpensive. S Cam and shaft need the wheels and drum pulled for replacement.

How Do I Know If My Slack Adjuster Is Bad?

If the brake pedal feels soft or brake wear is uneven, your slack adjuster may be bad.

How Do You Back Off Auto Slack Adjuster?

To back off an auto slack adjuster, remove the snap ring, then detach the slack adjuster from the S-cam. Finally, install the new slack adjuster and set the brake adjustment. Remember that some may require cutting the S-cam for removal.

Conclusion

Removing a slack adjuster may appear daunting, but with the right tools and careful technique, it can be accomplished effectively. Whether dealing with a frozen or bad slack adjuster, using proper equipment and understanding the process is essential for successful removal.

By following the recommended steps and safety measures, you can ensure a smooth and efficient slack adjuster removal process.