To determine if the tractor protection valve is faulty, check if air continues to leak from the gladhands after engaging the service brakes with the trailer service line turned off. If it leaks, it indicates a problem with the valve.

Tractor protection valves safeguard the tractor air brake system during a trailer breakaway or severe air leak, and they are used to shut off air to the trailer before disconnecting the lines. A bad tractor protection valve can lead to potential loss of control over the trailer’s emergency brakes.

Understanding how to identify issues with the tractor protection valve is crucial for safe operation and maintenance of commercial vehicles. In this informative guide, we’ll explore the signs of a bad tractor protection valve and how to effectively troubleshoot the system, ensuring a reliable and safe braking system for your tractor-trailer combination.

Navigate As You Want:

How To Test Tractor Protection System

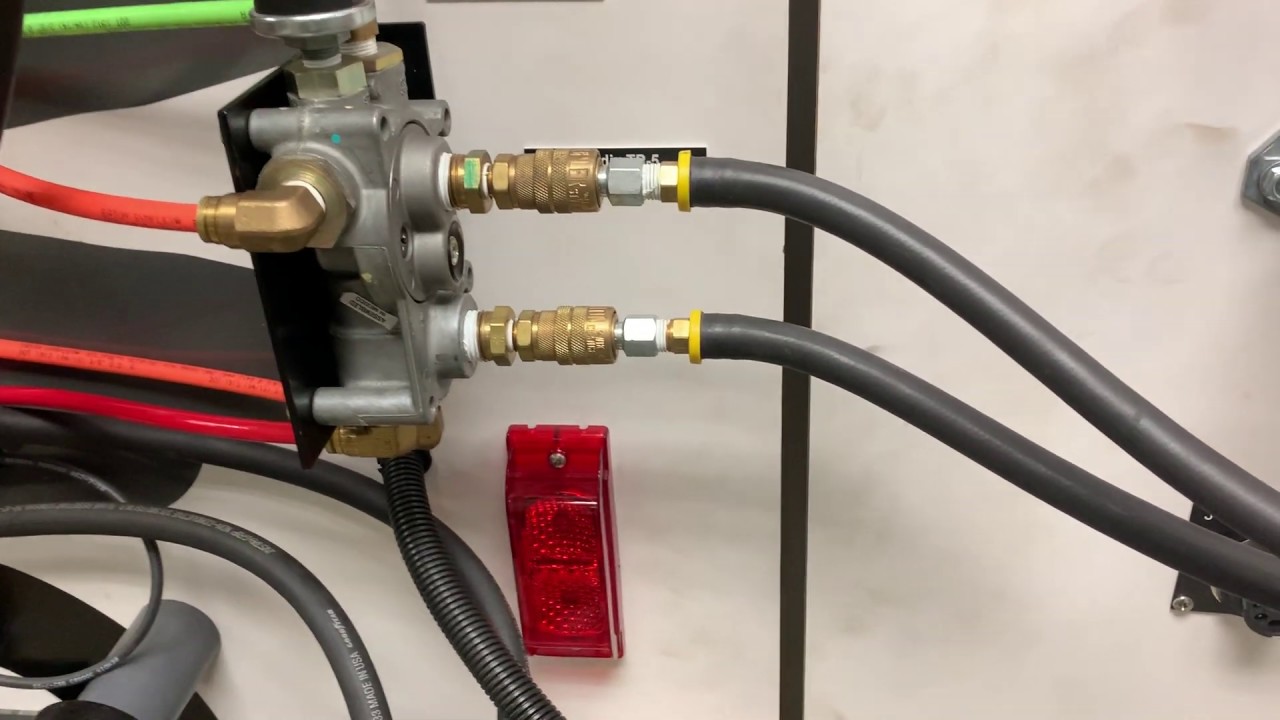

To test a tractor protection valve, make a service brake application and check for air leaks from gladhands. Then perform a trailer air supply shutoff test and inspect the trailer air supply valve. If there are no leaks, the valve is likely functioning correctly.

| To test a tractor protection valve, first make a service brake application. Next, perform a shutoff test on the trailer air supply. Then, test the air supply valve and the trailer air supply valve. Finally, disconnect the trailer to complete the tests. |

Credit: www.youtube.com

How To Replace A Tractor Protection Valve

To replace a tractor protection valve, you’ll need a set of wrenches, thread tape, and safety gloves. Removing the old valve involves disconnecting the air supply lines and unbolting the old valve from its mount. Then, you can install the new valve fitting in its place and secure it tightly. Applying thread tape to the valve’s connections will help prevent air leaks and ensure a proper seal.

Common Issues With Tractor Protection Valve

Common Issues with Tractor Protection Valve: A common issue with the tractor protection valve is an air leak, which can lead to a loss of air pressure in the brake system. This can compromise the proper functioning of the brakes. Another issue is the tractor protection valve not locking in place, which can result in the valve failing to activate when needed, posing a safety risk. It’s important to regularly inspect and maintain the tractor protection valve to avoid these issues.

Credit: m.youtube.com

Credit: www.smartdrivetest.com

Frequently Asked Questions For How To Tell If Tractor Protection Valve Is Bad

How Do You Test A Tractor Protection Valve?

To test a tractor protection valve, make a service brake application and check for any air leaks from the gladhands. The valve should prevent air from escaping when the brakes are engaged. Additionally, turn off the trailer service line to ensure the valve is functioning properly.

What Happens When The Tractor Protection Valve Is Closed?

When the tractor protection valve is closed, it stops the air from coming out of the tractor and releases the air from the trailer emergency line. This can activate the trailer emergency brakes and potentially lead to a loss of control.

When Should Tractor Protection Valve Pop?

Tractor protection valve should pop in case of trailer breakaway or severe air leak to protect the brake system.

What Does Tractor Protection Valve Do?

The tractor protection valve protects the tractor air brake system in case of a trailer breakaway or air leak. It also shuts off air to the trailer before disconnecting the lines.

Conclusion

When it comes to your tractor’s protection valve, ensuring it functions properly is crucial. Detecting issues early can prevent potential risks and ensure safe operations. Stay mindful of any irregularities and address them promptly to maintain optimal performance. Your safety is paramount.