To test the air compressor on a semi-truck, start by turning off the engine, draining the air tank, and disconnecting the air line. Then, use a pressure gauge to check the air pressure and look for any leaks.

Ensuring the air compressor on a semi-truck functions properly is crucial for safe and efficient operation. Regularly testing the air compressor helps prevent potential issues such as brake system failure and loss of air pressure essential for vehicle control. By following simple steps, truck drivers and maintenance personnel can ensure the compressor is in good working condition.

This article outlines the necessary procedures and tools for testing the air compressor on a semi-truck, providing valuable insights for maintaining the safety and reliability of commercial vehicles.

Credit: www.roadtrains.com.au

Navigate As You Want:

Preparing For The Test

Preparing for the test involves checking the air compressor system on a semi truck. Before starting, gather all the necessary tools and equipment. Here are the steps to follow:

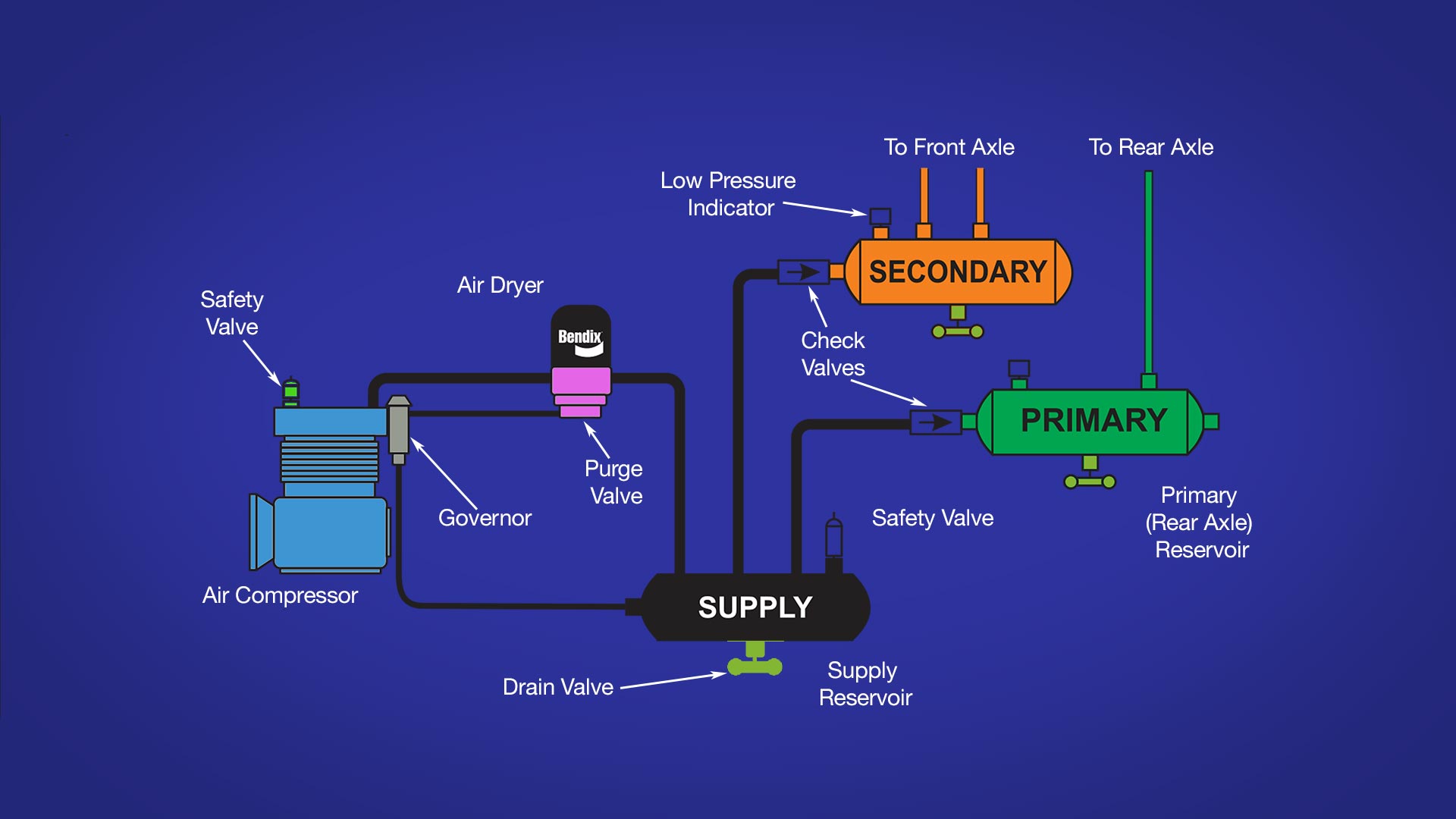

- Begin by visually inspecting the air compressor system for any signs of damage or leaks.

- Check the air compressor belt tension and condition, ensuring it is tight and in good condition.

- Inspect the air compressor governor for proper operation, ensuring it is functioning correctly.

- Next, locate the air compressor drain valve and ensure it is closed tightly.

- Inspect the air compressor filter and clean or replace it if necessary.

- Check the air dryer system for any signs of moisture or contamination and address any issues that are found.

- Lastly, check the air compressor pressure relief valve for proper operation.

By following these steps, you can ensure that the air compressor system on your semi truck is in good working condition before testing.

Performing The Air Compressor Test

When checking the pressure gauge, ensure it falls within the recommended range to ensure proper operation of the air compressor.

Listening for abnormal noises such as clanking or grinding during operation can indicate potential issues with the air compressor that need to be addressed promptly.

Inspecting The Compressor Components

Inspecting the air compressor on a semi truck is crucial for ensuring smooth operations. Start by examining the belts and pulleys for any signs of wear or damage. Check for any hoses and connections that may be leaking or deteriorating. Pay close attention to the condition of the components to prevent potential issues while on the road.

Credit: www.smartdrivetest.com

Testing The Compressor’s Functionality

Testing the functionality of an air compressor on a semi truck is crucial for ensuring its optimal performance. To engage the compressor, start by turning on the engine and allowing it to warm up. Next, locate the compressor switch and engage it by pressing it on. Once engaged, you can measure the air output using a gauge. Connect the gauge to the compressor’s air output valve and observe the reading. The desired pressure should be mentioned in the truck’s manual, so compare the gauge reading to the recommended pressure. If the reading is lower, check for any leaks. Inspect the air hoses, connectors, and valves for any signs of damage or faults. Repair or replace any faulty components immediately. Regularly testing and maintaining the air compressor will ensure its proper functioning and prevent any issues during long drives.

Troubleshooting And Maintenance

Regular maintenance is crucial to ensure the proper functioning of the air compressor on your semi truck. By performing routine checks and inspections, you can avoid potential issues and keep your compressor in top condition.

One common problem with air compressors is excessive oil consumption. This can be identified by checking the oil level regularly and looking for any signs of leakage or excessive oil consumption. Another issue is air leaks, which can be detected by listening for hissing sounds or using a soap and water solution to check for bubbles around the compressor fittings.

Clogged filters can also impact the performance of your air compressor. It is important to clean or replace the filters regularly to prevent airflow restrictions. Additionally, checking and maintaining the belts and pulleys can help avoid any potential issues.

| Common Air Compressor Issues | Troubleshooting Steps |

|---|---|

| Excessive oil consumption | Check oil level for leaks and consumption |

| Air leaks | Listen for hissing sounds or perform soap and water test |

| Clogged filters | Clean or replace filters regularly |

| Belt and pulley maintenance | Regularly check and maintain belts and pulleys |

Credit: www.amazon.com

Frequently Asked Questions For How To Test Air Compressor On Semi Truck

How Do I Test The Air Compressor On My Semi Truck?

To test the air compressor on your semi truck, start by checking for leaks and ensuring the compressor is properly connected. Turn on the engine and listen for any unusual noises. Next, check the air pressure gauges and make sure they are reading correctly.

Finally, engage the brakes and listen for the sound of the compressor kicking on and off.

Why Is It Important To Test The Air Compressor On A Semi Truck?

Testing the air compressor on a semi truck is important for safety and functionality. A properly functioning compressor ensures the brakes work properly, allowing for efficient stopping power. Regular testing helps detect any issues early on, preventing potential accidents caused by brake failure.

How Often Should I Test The Air Compressor On My Semi Truck?

It is recommended to test the air compressor on a semi truck at least once a month, or before embarking on a long journey. Regular testing ensures the compressor is in good working condition and helps identify any potential problems before they escalate.

What Are The Signs Of A Faulty Air Compressor On A Semi Truck?

Some signs of a faulty air compressor on a semi truck include the loss of air pressure, unusual noises coming from the compressor, difficulty in engaging the brakes, and longer braking distances. If you notice any of these signs, it is important to have your compressor checked by a professional mechanic.

Conclusion

Testing the air compressor on a semi-truck is essential for ensuring optimal performance and safety. By following the step-by-step guide provided in this blog post, you can easily diagnose and determine any issues with your air compressor. Regularly testing and maintaining your air compressor will help prevent breakdowns and costly repairs down the line.

Keep your semi-truck running smoothly and efficiently with these simple testing techniques.