To use a semi truck air hose, securely connect one end to the trailer’s air supply valve and the other end to the truck’s air brake system. Ensure the hose is free from kinks or damage, and always follow the manufacturer’s guidelines for proper installation and maintenance.

Using the air hose incorrectly can lead to brake system failure and potential accidents. Properly connecting and maintaining the air hose is crucial for the safety and functionality of the semi truck’s braking system. By understanding the essential steps and precautions for using a semi truck air hose, drivers can ensure the safe and efficient operation of their vehicles.

Let’s explore the key aspects of using a semi truck air hose and the importance of proper maintenance to prevent potential issues on the road.

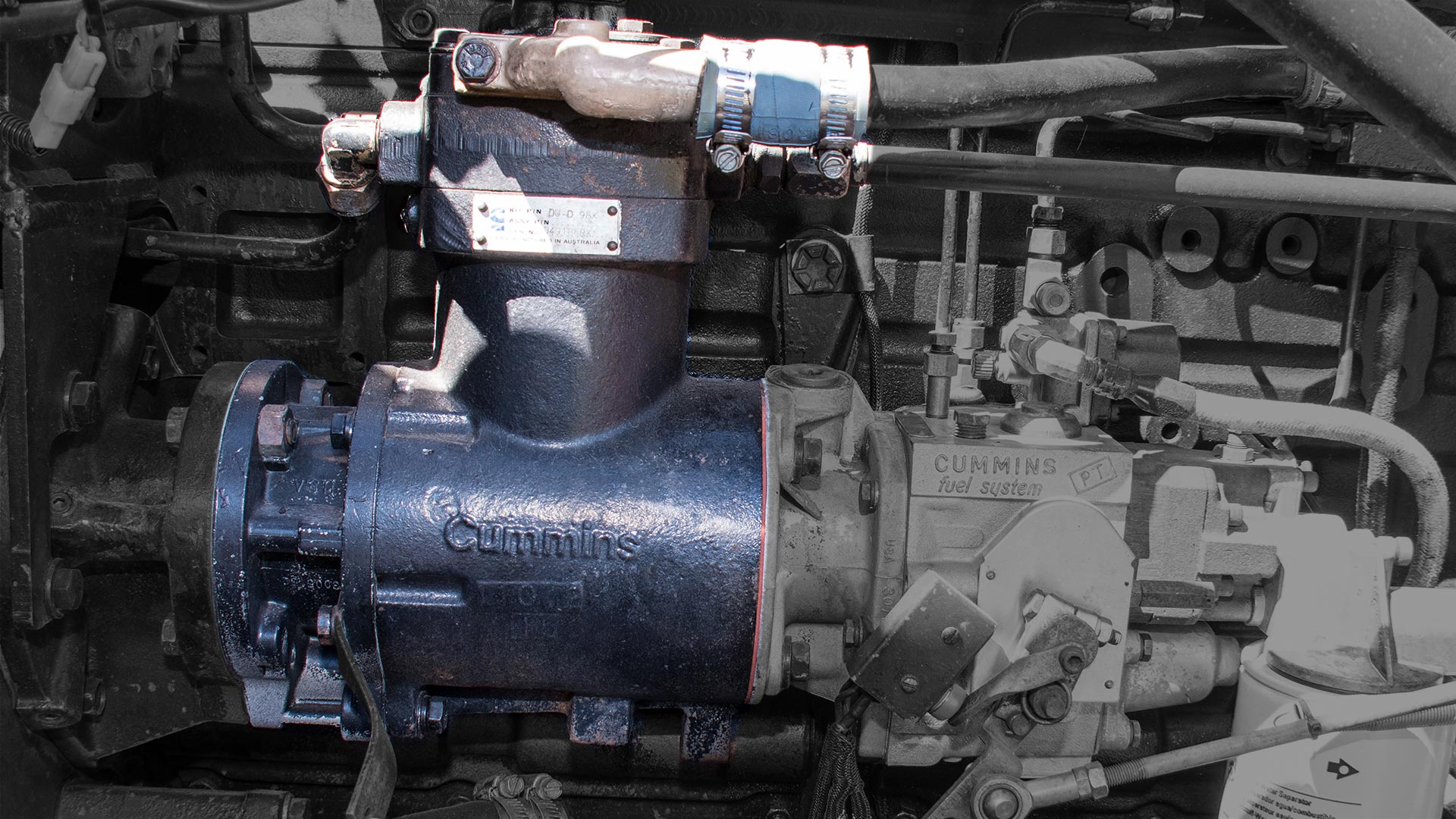

Credit: www.roadtrains.com.au

Navigate As You Want:

Checking The Air Hose

Checking the Air Hose:

Semi truck air hose is a crucial component for maintaining optimal performance. It is essential to periodically inspect the air hose to ensure its efficiency and safety.

Inspecting the Air Hose:

- Identifying Damage: Regularly check for signs of wear and tear, such as cracks, abrasions, or leaks. Pay attention to any bulges or unusual swelling as it may indicate internal damage.

- Proper Fittings: Ensure that the air hose has secure fittings and connections. Loose or damaged fittings can lead to air leaks and compromise the overall performance of the system.

- Clearance: Verify that the air hose has sufficient clearance and is not in contact with any sharp edges or moving parts. Friction or rubbing against other components can cause damage over time.

- Replace as Necessary: If you notice any significant damage or wear on the air hose, it is important to replace it immediately. Ignoring or neglecting damaged hoses can lead to air pressure loss and potential accidents.

Regularly inspecting and properly maintaining the semi truck air hose is crucial for safe and efficient operation. By following these guidelines, you can ensure the longevity and reliability of your air hose, enhancing your overall driving experience.

Credit: www.alamy.com

Connecting The Air Hose

When connecting the semi truck air hose, start by locating the connection point under the truck. Look for the red emergency line gladhand, which is used for supplying air to the trailer’s emergency air brake system.

Once you have found the connection point, attach the air hose to the gladhand by aligning the hose coupling with the gladhand and pushing it on until it locks into place. Ensure a secure connection by checking for a clear visual indication that the hose is fully engaged.

Using The Air Hose For Inflation

| Selecting the Correct Attachment | Inflating Tires or Equipment |

| The first step is to select the appropriate attachment for the job. Ensure it matches the size of the valve to avoid any leaks. | When inflating tires or equipment, always check the recommended pressure levels to prevent overinflation. |

Connect the air hose to the compressor, making sure the connection is secure. Begin by gradually inflating the tire or equipment to the desired pressure level.

Once inflated, carefully remove the attachment and secure the valve. Regularly inspect the air hose for any signs of wear and tear to ensure safe and efficient use.

Credit: www.amazon.com

Using The Air Hose For Brake System

Learn how to effectively use the air hose for your semi truck’s brake system to ensure optimal performance and safety on the road. Mastering the proper technique can help prevent accidents and maintain the longevity of your brakes.

Using the Semi Truck Air Hose for the Brake System is an essential aspect of maintaining the truck’s safety and performance. The air hose plays a crucial role in ensuring adequate brake pressure, thereby preventing accidents and ensuring smooth operation. Regularly checking the brake pressure is crucial for identifying any potential issues and ensuring the system is functioning optimally. Additionally, performing brake adjustments as needed is important for maintaining the proper balance and responsiveness of the brakes. By keeping a close eye on the brake pressure and performing necessary adjustments, truck drivers can ensure their safety and the safety of others on the road.

Disconnecting The Air Hose

In order to disconnect the air hose, you first need to release the air pressure. Start by locating the air hose coupling, which is typically found at the back of the cab or in the trailer’s landing gear area. To release the air pressure, slide the latch on the coupling back and push the coupling forward, away from the trailer. This will allow the air pressure to escape. Make sure to stand clear of the coupling as the air can be forceful. Once the air pressure is released, you can proceed to remove the air hose. Gently twist the hose counterclockwise to loosen it from the coupling. Pull the hose away from the coupling to fully disconnect it. Be cautious and avoid bending or kinking the hose during this process. With these steps, you can safely and effectively disconnect the air hose from your semi truck.

Frequently Asked Questions On How To Use Semi Truck Air Hose

How Does A Semi Truck Air Hose Work?

A semi truck air hose works by connecting the truck’s air brake system to the trailer. It allows compressed air to flow from the truck’s air tanks to the trailer’s brake system, activating the brakes when needed and ensuring efficient stopping power.

What Are The Different Types Of Semi Truck Air Hoses?

There are mainly two types of semi truck air hoses – coiled and straight. Coiled air hoses are flexible and retractable, while straight hoses are rigid and fixed in length. Both types serve the same purpose of connecting the truck and trailer’s air brake systems.

How Do You Properly Use A Semi Truck Air Hose?

To use a semi truck air hose, first, ensure the truck and trailer are fully connected. Then, securely attach the air hose to the truck’s gladhand fitting and the trailer’s air coupling. Once connected, check for any leaks, and if everything looks good, release the brakes and you’re ready to go.

How Often Should Semi Truck Air Hoses Be Inspected?

Semi truck air hoses should be inspected regularly, ideally during routine maintenance checks or before long trips. Look for any signs of wear, abrasions, cracks, or leaks. If any damage is found, replace the hose immediately to avoid potential brake failure or loss of braking power.

Conclusion

To successfully use a semi truck air hose, it is essential to understand its function and follow proper safety precautions. Regular inspection and maintenance of the air hose is crucial for optimal performance and to prevent potential accidents. By familiarizing yourself with the different components and their functions, you can operate the air hose effectively and ensure a smooth and safe journey on the road.

Remember, maintaining and using the semi truck air hose correctly is not only a legal requirement but also essential for your own safety and the safety of others. So, take the time to learn and master the art of using the semi truck air hose, and you can enjoy a trouble-free driving experience.